Industrial

Raythink’s products are utilized across various industrial sectors, including semiconductors, automotive maintenance, metallurgy, glass, mechanical casting, oil and gas, and petrochemicals. Their primary applications involve monitoring device temperatures, detecting defects, and assessing heat loss. By utilizing infrared thermal imaging technology, non-contact detection can be achieved, allowing for the timely identification of device defective and production-related issues. This enhances production efficiency and product quality, optimizes device operational efficiency, and ensures the safe and stable conduct of industrial processes.

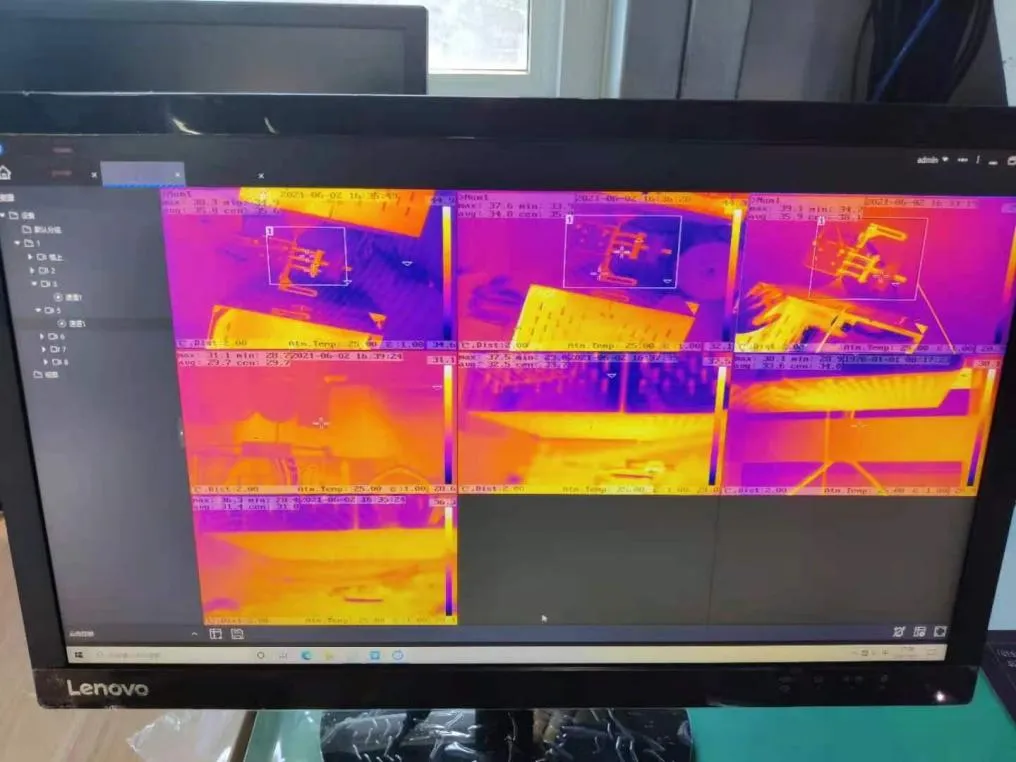

Application of Thermal Camera – Testing of Cable Encapsulating

1.Application Background In cable manufacturing, an insulating layer is created by evenly and hermetically wrapping the lead with a coat of non-conductive material, which prevents

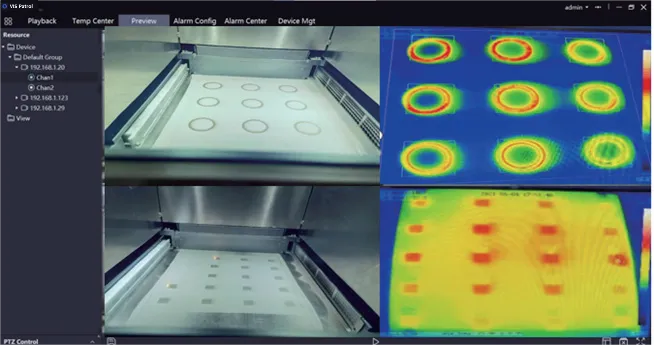

Thermal Camera Solution for 3D Laser Printing Inspection

1.Application Background 1)Industry Background The 3D laser printing technology is a widely researched additive manufacturing technology. Integrating CAD, material processing and forming technology and based

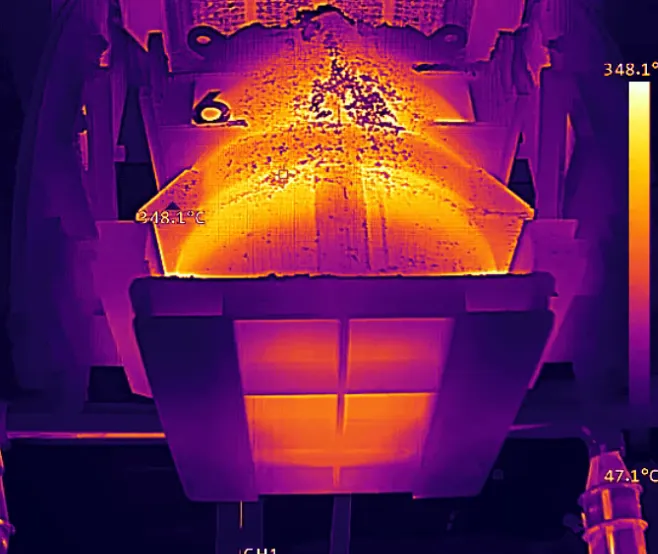

Thermal Imaging Applications in Parts Quenching Processing Monitoring

Learn about the powerful thermal imaging applications used in monitoring parts quenching processing. Improve quality, consistency, and production performance.

Infrared Thermal Imaging Solutions for Mechanical Casting

Facing challenges in mechanical casting? Learn how thermal imaging solutions offer innovative approaches for temperature control, defect identification, and overall process improvement.