In modern production and business activities, temperature is an important parameter indicating whether equipment operation is reliable. Some enterprises regularly measure equipment temperature to ensure the reliability and safety of equipment operation. Infrared thermometers and infrared thermal cameras use non-contact means of temperature measurement and have a wide range of applications in inspection and spot checks.

So what is the main difference between infrared thermometers and infrared thermal cameras? This article will answer this question in detail.

Infrared Thermometer Vs Thermal Camera

1. Measuring Principle and Output Forms

Infrared Thermometer

An infrared thermometer is also known as a spot thermometer or spot temperature gun. It also uses the principle of infrared radiation for temperature detection. However, it only measures the temperature of a single point and the temperature can only be output as a numerical value, not as an image.

Infrared Thermal Camera

An infrared thermal camera is a kind of photoelectric detection equipment. It is used to detect the infrared radiation of the object and will transform the infrared radiation into a thermal image. The surface temperature of the whole object can be displayed in real time, clear and intuitive, and easy to analyze and judge.

2. Measurement Range and Accuracy

Infrared Thermometer

An infrared thermometer measures the average temperature over an area called the “spot size”. As you move farther away from the target, the larger the measured area becomes (the spot size becomes larger). The ratio of distance to spot size, usually expressed as D:S, refers to the smallest area of an object that an infrared thermometer can accurately measure at a specific distance. For example, if a spot thermometer has a D:S ratio of 1:30, this means that at a 30-centimeter measuring distance, the spot thermometer can accurately measure the temperature of a target with a 1-centimeter diameter.

If the target is smaller than the spot size, the detector may detect radiation around the target object. Thus, the infrared thermometer detects not just the temperature of the target, but the combined temperature of the target and its surroundings.

Here’s an example to help you better understand this point:

- lIf you use an infrared thermometer to measure the temperature of a small screw, no matter how far the observation distance is, as long as the screw is a little larger than the measurement area (spot size), you will get an accurate reading.

- lHowever, if you use it to measure the temperature of a large pot while standing too far away, as long as the pot is a little smaller than the measurement area (spot size), the infrared thermometer may measure the pot along with the surrounding tabletop, so the result will not be accurate.

When the target size is more than twice the spot size, the error in the actual measurement will be relatively small.

Infrared thermometers typically have low D:S ratios, such as D:S ratios of its industrial type are mostly between 10:1 and 50:1, which means that it usually can only measure a target with a 1-centimeter diameter at distances from 10 to 50 centimeters. This limits its ability to accurately measure small targets far away.

Infrared Thermal Camera

The thermal imaging camera manufacturers do not usually specify the D:S value, but use the Instantaneous Field of View (IFOV) instead.It refers to the smallest target (area) that each pixel of the infrared thermal imager sensor can detect at a unit test distance, with mrad as the unit.Detection distance = target size ÷ IFOV, so the smaller the IFOV, the farther you can measure.

Common IFOV Ranges for Infrared Thermal Cameras

High-performance infrared thermal cameras typically have an IFOV between 0.2 mrad (telephoto lenses) and 2.0 mrad (standard lenses). Some basic models may have a larger IFOV, such as 3.0 mrad or more, which can limit their accuracy at long distances. Taking Raythink’s CX200+ Handheld Thermal Camera as an example, the IFOV of this model is 3.75mrad which means that when measuring a target with a 1cm diameter, the maximum detection distance is 10mm/3.75mrad ≈ 2.67m.

As you can see, even basic-level thermal cameras have a much longer measuring distance than highly configurable infrared thermometers. This is because, for observing 1cm objects, the maximum observation distance of infrared thermometers is 0.5m, while the observation distance of thermal imagers can reach several meters or even farther.

Each pixel of an infrared thermal camera corresponds to a temperature value. An infrared thermal camera is equivalent to the arrangement of hundreds or even thousands of infrared thermometers, capable of simultaneously capturing thousands or even millions of temperature points to create a complete thermal image. The advantages of an infrared thermal camera in this term over an infrared thermometer are self-evident.

3. Capability to Measure Small Objects

As mentioned above, infrared thermometers are limited in their ability to measure the temperature of small objects. This capability is becoming increasingly important in electronic component inspection. As many electronic devices continue to incorporate more components into smaller packages, finding ways to identify hot spots becomes increasingly challenging.

An infrared thermometer can effectively detect and measure temperature, but its spot size may be too large to measure very small components. However, an infrared thermal imaging camera equipped with a close-up lenses can easily address this challenge, assisting engineers and technicians in detecting the temperature of small targets.

4. Performance Differences

There are five main differences in performance between the two:

① An infrared thermometer measures the average temperature in a circular area, an infrared thermal camera measures the temperature distribution of a surface;

② An infrared thermometer can not display the visible image, an infrared thermal imaging camera can shoot a visible image like a normal camera;

③ An infrared thermometer can not produce infrared thermal images, an infrared thermal imaging camera can produce real-time infrared thermal images;

④ An infrared thermometer has no data storage function, an infrared thermal camera can be data storage and annotation;

⑤ Handheld infrared thermometer has no function to output data, an infrared thermal camera has the output function.

Specifically, compared with an infrared thermometer, an infrared thermal imaging camera has 4 core advantages: safety, intuition, high efficiency, and prevention of missed detection.

Example: How Is the Performance of an Infrared Camera Better Than That of an Infrared Thermometer?

1. Infrared Thermal Cameras for More Comprehensive and Safer Temperature Measurement

As the overall temperature distribution of the target can be captured, using an infrared thermal imager can quickly find high and low-temperature points, to avoid missed detection.

If you have used an infrared thermometer before, you probably understand the experience well. Scanning an electrical cabinet about 1 meter high with an infrared thermometer requires repeatedly moving back and forth to ensure no high-temperature spots are missed, which could lead to safety hazards. It usually takes at least a few minutes.

In contrast, using an infrared thermal imaging camera allows you to complete the task in just a few seconds. The most important advantage is that the temperature of this whole area in the image is clear at a glance, with absolutely no risk of missing anything.

2. Infrared Thermal Cameras Are Clearer in Data Display and Safer in Distance Measurement.

Although the infrared thermometer has a laser pointer, this only indicates the measured target, not equal to the specific temperature point to be measured. Usually, the temperature measurement data shows the average temperature of the corresponding target area, but most users will mistakenly think that the temperature value displayed on the screen is the temperature of the laser point. It is not!

Infrared thermal imaging cameras do not have this issue, as they display the overall temperature distribution. Additionally, most handheld thermal cameras on the market come equipped with laser pointers and LED lights, facilitating quick on-site positioning and identification.

For certain inspection environments with safety distance requirements, standard infrared thermometers cannot meet the demands. This is because as the measurement distance increases, the target area for accurate detection also expands, which naturally affects the accuracy of the temperature readings. Infrared thermal cameras’ long-distance measurement allows users to obtain accurate measurements from a safe distance. Compared to infrared thermometers, using infrared thermal cameras provides better safety for the user.

Example: Rotary Kiln Shell Temperature Measurement

A rotary kiln is a high-temperature processing device used to heat materials to high temperatures through calcination in a continuous process. It is widely applied in industries such as construction materials, metallurgy, chemical engineering, and environmental protection. Its main functions are as follows:

- Sintering and Solidification: The rotary kiln calcines materials at high temperatures, causing chemical reactions and physical changes to achieve sintering and solidification. This process enhances the material’s density, mechanical strength, and chemical stability.

- Waste Treatment: The rotary kiln can also be used for waste treatment, such as processing waste plastics, waste rubber, waste oil, and waste minerals. Under high-temperature conditions, these wastes undergo pyrolysis, cracking, or oxidation reactions, transforming into useful products or safe, harmless substances.

- Ore Refining: In the metallurgical field, the rotary kiln is used for ore refining processes involving metals such as aluminum, iron, and nickel. High-temperature chemical reactions enable the extraction and separation of valuable metals from ores, resulting in high-purity metal products.

As a high-temperature equipment, the rotary kiln has a thicker lining of refractory material and a thick steel plate on the surface for protection. During operation, the internal refractory material gradually erodes and may even fall off in some cases. Once the refractory material is eroded to a certain extent or falls off, the high temperature directly affects the kiln’s steel plates. If not addressed in time, the steel plates may soften or melt, potentially causing serious accidents. Therefore, it is particularly critical to use effective methods to diagnose defects in the rotary kiln lining.

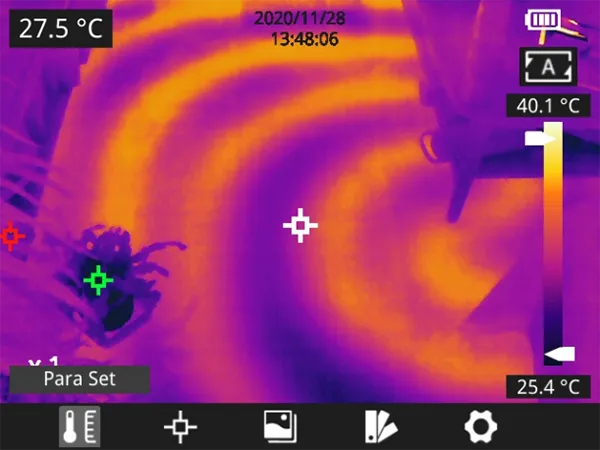

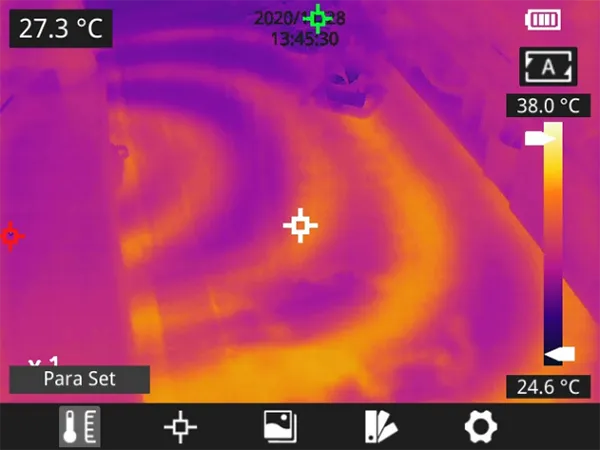

The surface temperature of the kiln body will rise abnormally at the location where the refractory material is eroded or falling off. The infrared thermal imager can directly detect the abnormal temperature on the surface of the kiln body and address the problems in time to avoid accidents.

For such ultra-high temperature scenarios, long-distance monitoring is required to ensure the safety of inspection personnel. Under these circumstances, the advantages of an infrared thermal imager over an infrared thermometer become quite evident. It not only allows for large-scale and long-distance detection but also provides a clear view of the temperature distribution across an entire area through the thermal image.

5. Applications

Infrared Thermometer

Infrared thermometers focus on measuring object temperatures and identifying hotspots. By adjusting the upper and lower temperature detection limits, they can locate objects with specific temperatures.

In the medical field, infrared thermometers are commonly used for body temperature measurement, especially in public places or during pandemics, where they enable rapid, non-contact temperature screening. In construction, infrared thermometers can measure the temperature of building materials such as concrete and asphalt to ensure construction quality. In environmental monitoring, infrared thermometers can measure atmospheric temperature, water temperature, and surface temperature, contributing to applications such as weather forecasting and water resource management.

Infrared Thermal Camera

After decades of development, infrared thermal cameras have gradually been applied to areas such as power systems, HVAC systems, metallurgy, petrochemicals, scientific research, product development, building inspections, and security.

For example, when locating HVAC leakage points, blindly chiseling and causing large-scale damage to floor is obviously time-consuming, labor-intensive, and more costly. Efficiently and non-destructively locating leakage points requires the right methods and auxiliary tools. Although thermal imagers do not have the ability to see through the floor, heat conduction provides temperature information for the thermal imager to see the distribution of floor heating.

Since the temperature of the hot water pipes under the floor is higher and the floor temperature is lower, the heat released by the high-temperature water pipes is transferred to the floor through heat conduction. Thus, the infrared thermal imaging cameras can easily capture the heat distribution of the heating pipes and visually present it in a thermal image. Once an area with abnormal temperature is detected, it can quickly and accurately pinpoint the suspected leakage point.

Conclusion

While infrared thermometers offer simplicity and affordability, their application is limited because they can only accurately measure the temperature of a specific point or area.The larger the target’s area being measured, the less accurate the data.

Compared to infrared thermometers,infrared thermal cameras have a much wider range of applications. Whether in close-range or long-distance scenarios, they can visualize the temperature distribution of large areas in real time, ensuring quick identification of abnormal temperature spots. Based on the thermal images captured and detailed analysis reports,users can deeply analyze temperature data and address the root cause of temperature anomalies.

In addition, infrared thermal imaging also has unique advantages over infrared thermometers in scenarios with long distances, ultra-high temperatures or complex terrain.

When deciding between an infrared thermometer and an infrared thermal camera, it ultimately depends on the specific needs of your work. However, given the broader application scenarios of infrared thermal cameras and their relatively higher cost-effectiveness, they are often the better choice.

.webp)