1.Application Background

1)Industry Background

The 3D laser printing technology is a widely researched additive manufacturing technology. Integrating CAD, material processing and forming technology and based on digital model files, additive manufacturing technology stacks special metal materials, non-metallic materials or medical bio-materials by means of extrusion, sintering, melting, light-curing, spraying, etc. through software and NC system to produce tangible objects.

Compared with the traditional processing mode which removes, cuts and assembles the raw material, it is a “bottom-up” manufacturing method through material accumulation, creating something new as result. This makes it possible to manufacture – complex structural components whose production was constrained by traditional manufacturing methods in the past. 3D laser printing, also known as high-energy beam current rapid manufacturing, employs laser beam, electron beam, plasma or ion beam to heat and combine materials so as to directly manufacture parts. It is a significant branch of additive manufacturing and is widely used in industry.

In the process of 3D laser printing, thermoforming is a key part. Due to the disparity of speed, distance, material, etc., when the powder stacks and accumulates, the abnormality of temperature (such as abrupt change, extra high or low temperature, fluctuation, etc.)occurs causing performance degradation of structural components, poor toughness, lack of elasticity, brittleness, hidden lines, etc. Therefore, it is critical to monitor the temperature of the material from thermal melting to forming, which is directly related to the molten state of the material, the temperature of material coating and molding, and the temperature change of the molding process. In the process from the material passing through the printing head to solidification, temperature is the most direct quantitative standard for monitoring. Accuracy and smooth changes of temperature ensure the production of qualified products.

2)Existing Solution and Problems

Currently, 3D printing at home and abroad adopts a “blind” printing process in general, which requires massive process statistics Traditional Thermometers and Thermocouples Monitoring Solution: and an extremely complex forming process. Repeated experiments are required for every kind of material and component in various shapes. However, there is no effective means for monitoring the temperature in the metal powder melting and solidification processes. Currently, thermometers are only used to measure the temperature of a point on the substrate at the beginning of the printing, but there are no effective measurement methods for temperature measurement of components to be printed at each layer during the printing process.

Thermometers can only be used at the beginning of the printing to measure the temperature of the substrate. However, after the Pain Point: printing process has started in a sealed space, no object is allowed to enter. In addition, thermometers can only monitor the temperature of a single point and cannot effectively monitor the entire laser printing process or trace the temperature curve changes during the process. Therefore, the needs of customers cannot be satisfied..

2.Customer Demands

Functional Requirements of the System

- Short-focus lens: Considering the relatively short installation distance and the need to clearly see the temperature distribution on the surface of the material and the temperature change process and choose a short-focus lens as much as possible.

- High frame rate: The printing speed of the material is fast. A length of 3mm needs to be completed in 1-2s. Hence, a frame rate of 50Hz is highly recommended.

- Wide temperature measurement range, -20℃-550℃, high precision, enable to meet the requirement of ±2℃. (The instantaneous temperature of the material can reach 1000°C when printing. During the solidification process, however, the temperature will drop rapidly to within 500°C. At present, we only need to pay attention to the temperature after solidification because it will affect the period of the next powder coating and decide whether to coat)

- Compact structure, rich interface, and support SDK-based secondary development.

- High temperature sampling frequency given the rapid change of the temperature in the process of metal melting and solidification. Collecting temperature data every 100ms is recommended.

- Real-time temperature monitoring: It is necessary to monitor the temperature changes and data of the printing surface in real time. The temperature sampling time is preferably less than 100ms, and the temperature curve can be drawn to confirm the process temperature of the new material.

- When the temperature is abnormal, alarm devices such as audible and visual alarms can be triggered to remind the staff and control the PLC to stop printing.

3.Onsite Application Scenarios

Infrared Camera Installation Position:

Thermal cameras are installed 50cm above the substrate through fixed bracket or guide rail. A certain tilt is required during installation to avoid the impact of the substrate reflection on the measurement accuracy.

Temperature Monitoring and Effects on Objects to be Printed of Different Sizes and Materials:

For temperature monitoring on objects to be printed of different sizes and materials, lenses with different focal lengths can be selected and the emissivity of the corresponding material can be adjusted to observe the details of the temperature distribution on the surface of each object to be printed and ensure the temperature measurement accuracy. During the metal melting and solidification process, once the temperature exceeds the warning threshold, the PLC operates in time to stop the powder coating of the next layer, and an audible and visual alarm can be triggered to remind the staff to check the running status of the equipment and the quality of the printed objects, thereby reducing the defective rate of finished products.

During the 3D laser printing process, a temperature distribution report and temperature curve image of printed objects can be generated, including the printing temperature and the temperature before and after powder coating. Customers can easily and efficiently grasp the working temperature of the additive print head and carry out research on the temperature measurement, forming temperature and cooling curve of the formed material. Through the exploration of the relationship between a large amount of infrared and temperature results and the quality of additive manufacturing products, more outcomes and experience in the production and processing technology, quality control, parameter control and material properties will be obtained.

4.System Solutions and Application Effects

1)Thermal Camera Solution for the 3D Laser Printing

Product Solution:

• Install the online thermal cameras 50cm above the substrate through fixed bracket or guide rail. A certain tilt is required during installation to avoid the impact of the substrate reflection on the measurement accuracy.

• Visual thermal monitoring covers the temperature of the objects to be printed on the entire substrate.

• For high printing speed conditions,AT31 series can be selected, with frame rates up to 50HZ.

• Alarm parameters can be configured based on the temperature characteristics of the detection area to realize pre-warning and alarms for abnormal temperature fluctuation of the objects to be printed before and after the powder coating.

• The thermal cameras can be connected to the 3D printer through network cables. Image display, temperature measurement, and alarm measurement/output then can be implemented. In addition, alarm thresholds can be configured for linkages operations of starting and stopping the powder coating device. The audible and visual alarm can be triggered to remind the staff to -keep an eye on the operational status of the device and the condition of the printed objects.

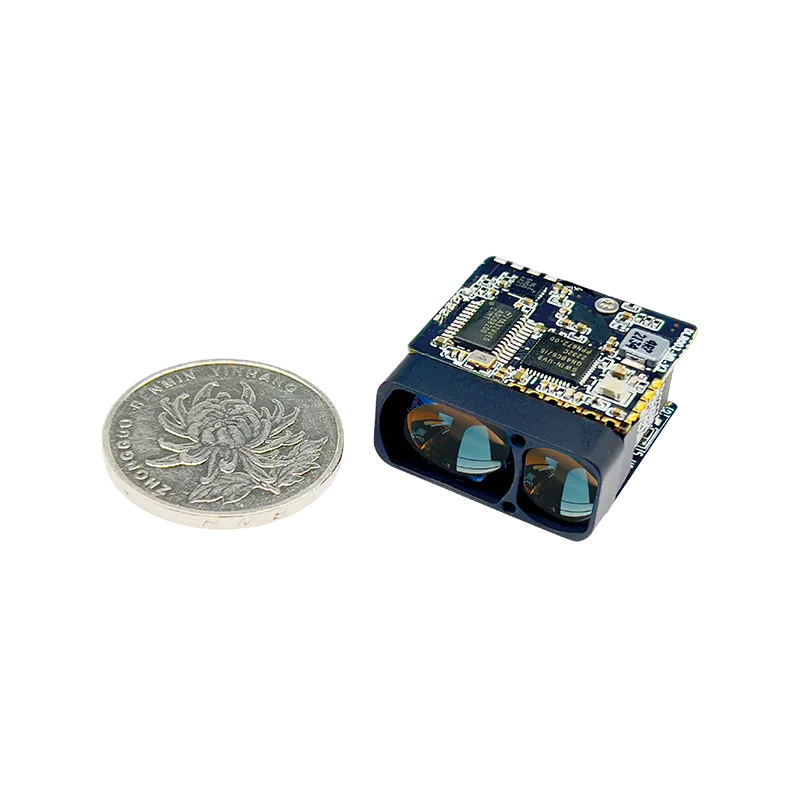

2)Recommended Motorized Focusing Thermal Camera by Raythink

Product Technical Features:

- Accurate temperature measurement, with the measurement range of -20°C ~550°C and measurement accuracy of ±2°C

- Support PoE power supply

- Support GB28181

- Support auto focus

- 50 Hz high frame frequency

- Simultaneous output of the temperature stream data and image stream data

- Support SDK-based secondary development on Linux and Windows for facilitating the integrated development of customers

- Online real-time monitoring of multiple devices when equipped with professional PC software, and ONVIF protocol supported

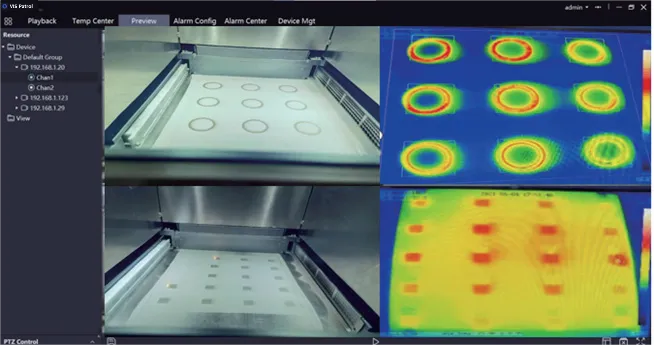

System Software: Customized software can be developed according to the SDK provided by Raythink. VIS Patro, an industrial temperature measurement

client developed by Raythink can also be used. VIS Patro supports the access of Raythink’s multiple series of temperature measurement products, such as AT, etc. Support real-time previews on up to 64 screens, alarm configuration, palette selection, temperature measurement tool configuration, automatic generation of temperature measurement data curves and reports.

5.Advantages and Disadvantages of Products/Solutions

Advantages:

all temperature points of the entire screen. The hottest spot on the entire screen or the area is automatically captured for users to directly identify the problem and efficiently locate problems without omission.

• Wide measurement range: Thermal cameras with different measurement ranges of from -20°C to 550°C and from 0° to 1500°C are provided to satisfy the needs of different customers.

• High frame rate: The 50Hz high-frame-rate thermal cameras can be selected to meet the customers’ requirement for temperature monitoring through the fast printing processes.