1. What Are Thermal Cameras Used For?

An infrared thermal imaging camera utilizes infrared thermal imaging technology to detect infrared radiation from target objects. Through signal processing and photoelectric conversion, it transforms the temperature distribution image of the target object into a visible thermal image. The thermal imaging camera accurately quantifies the detected heat and produces real-time imaging of the entire target object in a planar form, enabling precise identification of suspected fault areas that are generating heat.

Operators can timely assess heating conditions and fault locations through the color images displayed on the screen and its hot spot tracking function, while conducting rigorous analysis to improve the efficiency and accuracy of problem detection and resolution.

This unique functionality has led to its widespread application across various major industries, where it plays an irreplaceable role. This article will introduce these primary application areas of infrared thermal imaging cameras to help you better understand their role.

2. Main Thermal Imaging Applications

1) Monitoring Targets at Night and in Bad Weather Conditions

Traditional surveillance cameras have limited effectiveness at night due to light conditions, unable to provide clear images. However, infrared thermal imaging technology can not only capture infrared radiation emitted by objects in the monitored area but also analyze and identify different objects based on their heat signatures. This means that in dark conditions, infrared thermal imaging cameras can still monitor and track targets without exposing themselves.

Similarly, in adverse weather conditions such as rain or fog, traditional surveillance cameras perform poorly due to the short wavelength of visible light and their limited ability to overcome obstacles. However, infrared rays have longer wavelengths, especially thermal imagers operating in the 8-14μm range. They have a higher ability to penetrate rain and fog, allowing for normal target observation. Therefore, even in adverse weather conditions, infrared thermal imaging cameras can still monitor various targets effectively.

This technology has widespread application value in nighttime security patrols, perimeter monitoring, and night vision observation under bad weather.

2) Fire Prevention Monitoring

Since infrared thermal imaging cameras create images based on the surface temperature of objects, they can be used not only for on-site monitoring at night but also as effective fire alarm equipment.

In large forests, fires are often triggered by inconspicuous hidden fires. These are the root cause of devastating wildfires, and it’s difficult to detect such latent fire outbreaks using conventional methods. In contrast, if an infrared thermal imaging camera is used, it can promptly capture the thermal radiation from flames due to the fire’s high temperatures.

This allows us to quickly and accurately detect fire occurrences, discover hidden fires, and precisely determine the fire’s location and extent. It can also identify ignition points through smoke, enabling early awareness, prevention, and extinguishment.

Compared to traditional smoke detectors, infrared thermal imaging technology can provide earlier fire warnings, preventing fire spread. It offers effective fire monitoring and timely emergency response by transmitting fire information to the monitoring center in real time.

3) Identification of Camouflaged and Concealed Targets

Conventional camouflage primarily aims to prevent detection by visible light. Typically, criminals hiding in bushes and forests can be difficult to spot due to harsh outdoor environments and visual illusions, which can lead to misjudgments.

Infrared thermal imaging cameras passively receive thermal radiation emitted by the targets themselves. The temperature and infrared radiation of human bodies and vehicles are generally much higher than those of vegetation, making them difficult to camouflage and reducing the likelihood of erroneous judgments.

4) Intelligent Transportation

The rapid maturation of the front-end equipment market has driven the application of infrared thermal imaging cameras in intelligent transportation. Infrared thermal imaging cameras are not affected by low light conditions or strong sunlight, and can automatically eliminate the effects of shadows and adverse weather conditions, which is an unparalleled advantage over traditional surveillance cameras.

Whether day or night, thermal imaging cameras provide clear video images, unaffected by sunlight and almost impervious to other external environmental factors. They can monitor traffic flow and vehicle movement on roads. By clearly capturing the heat distribution of vehicles and pedestrians, they can analyze real-time traffic density, vehicle speeds, and pedestrian flow, thereby helping intelligent transportation systems make real-time traffic control and optimization decisions.

5) Coal Mining

Failures in electromechanical equipment such as motors and cables in mine shafts are the biggest safety killers causing coal mine accidents. Short circuits, sparks, and friction-induced temperature increases in equipment can all lead to mine fires. Explosion-proof thermal imaging cameras can monitor real-time temperature changes in the shaft through temperature variations and precise readings, nipping potential accidents in the bud.

Timely early warning reduces hidden dangers. Using explosion-proof thermal imaging cameras to conduct regular temperature checks on bearings and rollers of underground belt conveyors can prevent fire accidents. Through analysis of belt conveyor accidents, phenomena such as fires caused by friction between belts and metal, belt jams, belt slippage, and hydraulic coupling fires can be observed. Explosion-proof thermal imaging cameras can effectively detect existing safety hazards during belt operation, allowing for immediate handling and providing timely early warnings, thereby reducing or avoiding belt conveyor accidents.

6) Power Monitoring

Most thermal failures in electrical equipment are not sudden but often involve a change process. Faults in power distribution systems can be categorized as internal or external. External faults mainly refer to aging, loosening, or cracking of equipment or cable components, leading to increased contact resistance and localized heating. Internal faults primarily involve issues within the equipment’s electrical circuits, which are more concealed and difficult to detect through touch or visual inspection.

Using infrared thermal imagers can reveal these abnormalities in electrical equipment, identifying the location and severity of potential faults. Infrared thermal imagers offer advantages in diagnosing potential thermal faults in electrical equipment, including immunity to electromagnetic interference, non-contact operation, intuitive imaging, accurate judgment, safety and reliability, high efficiency, long detection distance, and fast inspection speed.

In addition to handheld thermal imaging cameras, there are inspection robots and drones equipped with infrared cameras that can perform all-weather, high-efficiency inspections of electrical equipment. The application of these technologies not only improves the reliability of equipment operation but also significantly reduces the cost of equipment maintenance, providing important safeguards for the safe operation and maintenance of power systems.

7) Oil and Petrochemical Industry

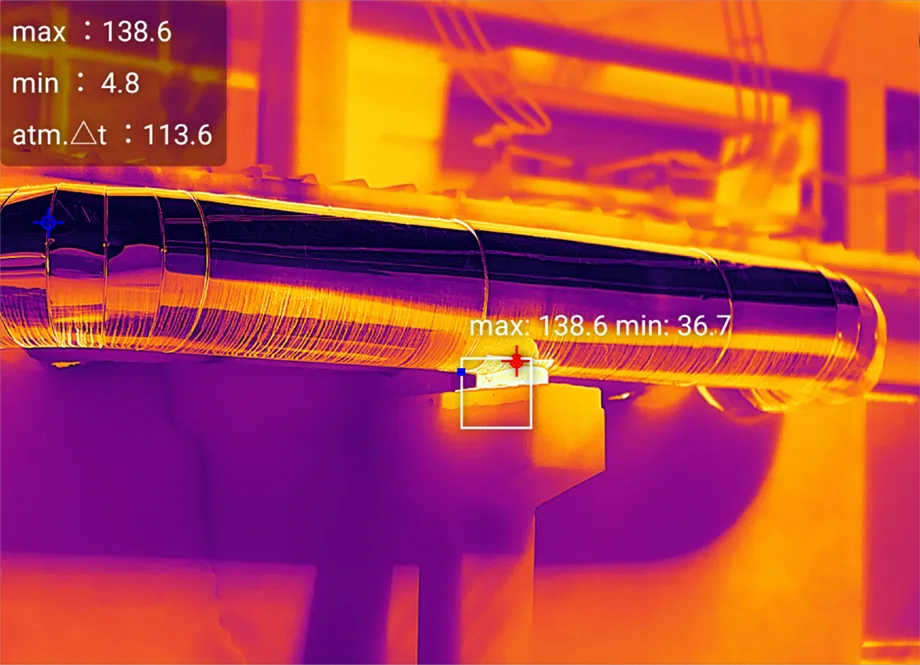

In petrochemical enterprises, due to production requirements, there are typically numerous pipelines carrying substances such as steam, hot water, and various industrial solutions. These pipes are usually covered with insulation materials to ensure energy efficiency. As these pipelines are often installed in the upper parts of factories or outdoors without any maintenance measures, over time, the insulation layer or even the pipe walls may become damaged or thinned.

Using thermal imaging cameras, it’s very easy to detect hot spots, allowing for measures to be taken to reduce energy waste and ensure correct process temperatures. Additionally, this technology can reveal the state of damage to the insulation layer, enabling precise calculation of the required manpower and materials, thereby greatly reducing repair workload and time.

Due to the involvement of numerous chemical reactions in production processes, especially in various types of reactors, certain temperatures usually come along with it, which may cause different degrees of corrosion. This is particularly evident in components such as valves, plate heat exchangers, and thinning end cap linings. In the early stages, these issues may manifest as simple leaks that are often undetectable to the naked eye. However, infrared thermal imaging cameras can detect these problems through subtle temperature changes, thereby preventing harm to both the environment and personnel.

Factories contain various types of equipment, both indoors and outdoors, which generally control materials through level sensors. Sometimes, we must deal with malfunctioning level sensors, often leading to overflow or flow interruption, causing production delays. Under such circumstances, using infrared thermal imaging cameras for detection is a better choice. Due to the different materials of the contents and storage equipment, which have different heat capacities,the liquid level can be reflected in the infrared thermal image. This can sometimes be a simple method for detecting liquid levels, avoiding many potential dangers.

For leaks of liquefied natural gas, liquefied petroleum gas, and liquefied ethylene, which are colorless and odorless, special instruments are often required for detection. If not addressed promptly, these leaks can lead to fires, explosions, and other disasters. While gas sensors can only detect at fixed points, gas thermal imaging cameras can survey large areas. They detect gas leaks based on environmental temperature changes caused by the gas release. When liquefied gas escapes, abnormal phenomena appear in the surrounding area, and thermal imaging cameras can determine the location and scale of the gas leak.

8) New Energy Power Batteries

With the popularization and development of new energy vehicles, the performance and safety of power batteries have received increasing attention. As one of the core components of new energy vehicles, the state monitoring and fault diagnosis of power batteries are particularly important.

Infrared thermal imaging technology can quickly obtain temperature data from various parts by scanning the battery surface, promptly identifying overheating points or areas with abnormal temperatures. This helps in early fault detection and maintenance, avoiding safety risks. Additionally, this technology can assess the thermal runaway risk of battery packs by monitoring temperature differences between individual cells and heat distribution, identifying overheating phenomena, and taking cooling or adjustment measures to ensure the stability and safety of the battery pack. Furthermore, infrared thermal imaging can analyze thermal effects during the charging and discharging processes, providing a basis for optimizing charging and discharging strategies and improving battery utilization.

Its rapid, accurate, and non-destructive characteristics make it an important tool in the field of new energy power battery inspection, helping to improve battery performance and safety, and extending battery life.

3. Conclusion

In summary, thermal imaging cameras, based on the principle of infrared radiation from objects, can create thermal images to display temperature distributions. They have applications in various fields including security protection, industrial inspection, new energy sectors. Compared to traditional cameras, thermal imaging cameras excel in dark or low-light environments and can accurately detect the temperature information of objects. This makes thermal imaging cameras an indispensable part of many application scenarios.

With ongoing technological advancements, the performance and application prospects of thermal imaging cameras will continue to expand.