1.Application Background

In cable manufacturing, an insulating layer is created by evenly and hermetically wrapping the lead with a coat of non-conductive material, which prevents the electric conductor from contacting the outside environment. This effectively prevents accidents such as electric leakage, short circuits, and electric shocks during cable usage.

The cable encapsulating workshop is equipped with multiple rubber preheating furnaces and vertical furnaces. First, the rubber material is melted in the preheating furnace. When the temperature reaches 60°C, the cable passes through the vertical furnace where it is wrapped with the melted rubber material.

An industrial thermal camera is used to monitor the workshop temperature in real time, automatically triggering alarms to prompt staff for timely intervention if abnormal temperatures are detected. This application of thermal camera technology helps improve product qualification rates and maintain high production efficiency.

2.Unique Advantages of Thermal Cameras

The industrial thermal camera monitoring solution enables all-weather, real-time monitoring of the cable workshop without requiring manual temperature measurements for each preheating furnace, reducing labor costs.

Equipped with professional industrial temperature measurement and monitoring software, it supports online networked monitoring of multiple thermal cameras, enabling integrated deployment and centralized monitoring of the entire workshop.

Thermal cameras provide clear visualization of cable positions. Their wide-angle lenses cover all monitored targets and deliver stable images.

Temperature measurement tools for points, lines, or areas can be configured with individual alarms to ensure prompt risk detection and handling.

3.Main Applications of Thermal Cameras in Testing of Cable Encapsulating

To ensure stable production and consistent product quality in cable manufacturing, an industrial thermal camera is installed at the top of the workshop using a fixed bracket, with its lens precisely aimed at critical high-temperature zones—specifically above the preheating and vertical curing furnaces. This setup enables comprehensive monitoring of the entire cable encapsulation process, covering all essential equipment and temperature-sensitive areas on the production line.

Accurate Monitoring of Furnace Temperatures

The thermal camera continuously measures the temperatures of the preheating and vertical furnaces, ensuring the rubber insulation material reaches and maintains a fully molten state throughout the process. Proper melting is essential for the rubber to flow and bond correctly to the cable core, ensuring a uniform and secure insulation layer.

Real-Time Surface Temperature Detection

In addition to furnace monitoring, the system captures the surface temperature of the cable in real time as it moves along the production line. This allows operators to track the thermal condition of the rubber layer—both on the surface and within the molten material—with high accuracy. Any temperature anomalies or uneven heating can be detected early, helping to prevent defects in the encapsulation quality.

Enhanced Process Visibility and Quality Control

Integrating thermal imaging technology gives manufacturers a powerful tool for real-time process visibility and precise thermal management. Early issue detection reduces scrap rates, improves process parameters, and ensures consistent product quality. This results in higher reliability and performance of the final cable products, meeting strict industry standards for insulation and safety.

4.Recommended Products

- AT Series is a high-performance and high-precision electrically adjustable temperature measurement thermal imager that uses a uncooled focal plane detector and offers multiple lens options.

- Supporting multiple protocols such as RTSP and Onvif, equipped with professional application software and universal SDK development package.

- It is ideal choice for fields such as electronic circuits, education and research, and industrial automation.

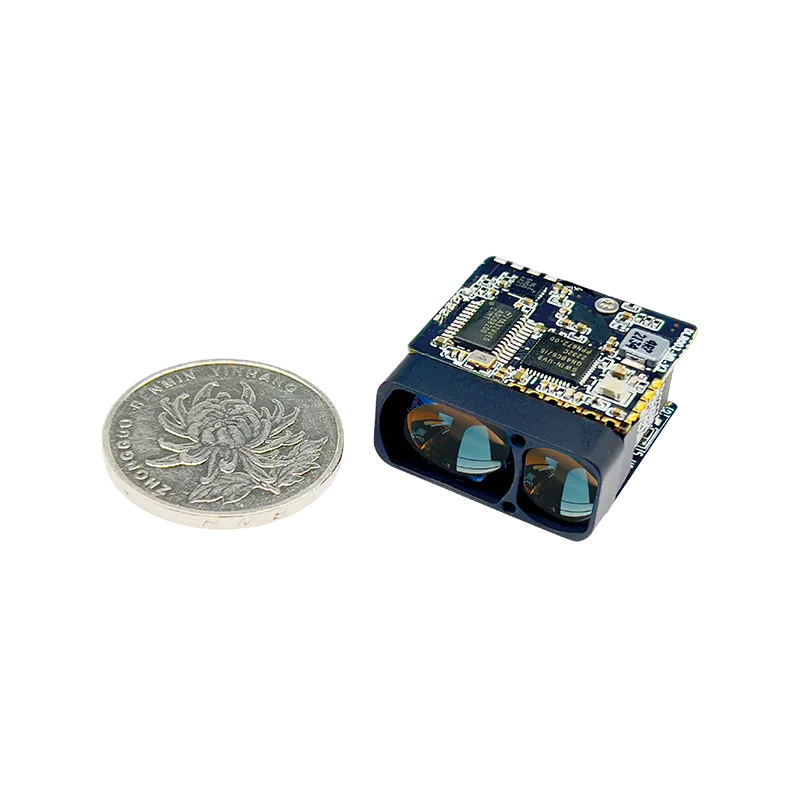

- TN430/TN460 is a high-performance and high-precision network type temperature measurement thermal imager that uses a uncooled focal plane detector and offers multiple lens options.

- Supports multiple protocols such as Modbus and Onvif, equipped with professional application software and universal SDK development package, with small size and low power consumption, making it easy to integrate industrial automation applications.

- Can output high-quality infrared images with a resolution of 384×288/640×512, providing clear and delicate infrared thermal images for temperature data analysis and determination.

- With a wide measurement range from -20°C to +650°C, suitable for industrial scenarios with various temperature requirements. The device utilizes a temperature compensation algorithm to adjust for environmental factors and ensure measurement accuracy and reliability.

5.Software Solution

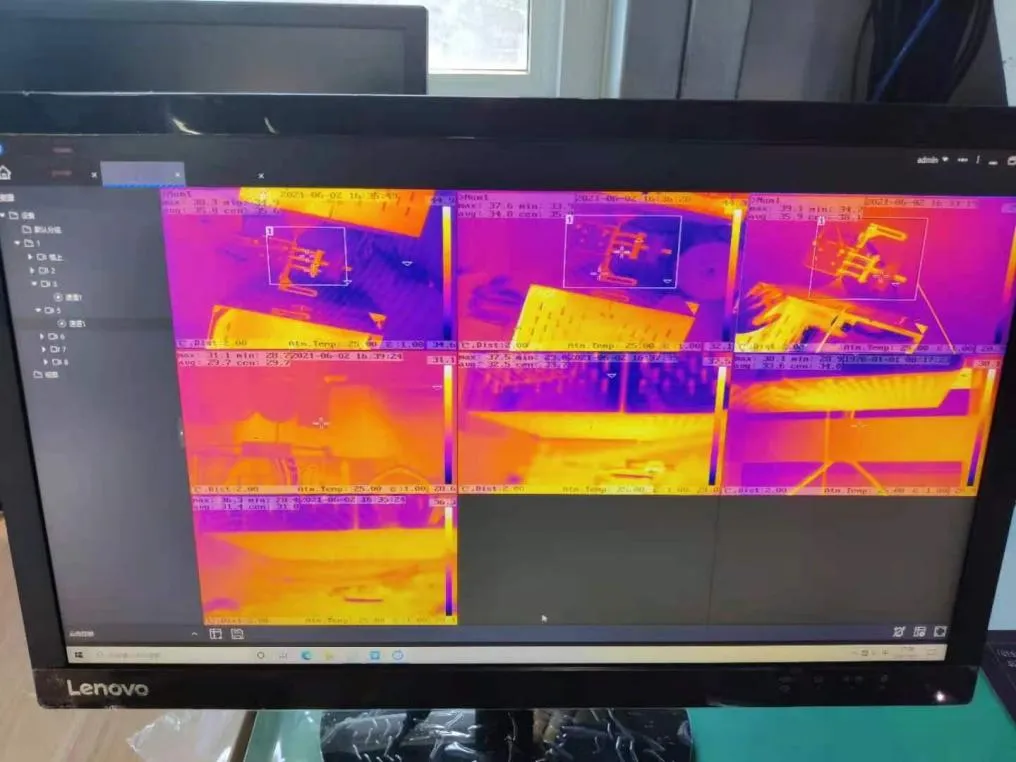

It is recommended to use the industrial thermal cameras with Raythink’s professional industrial temperature measurement and monitoring software VIS-Patrol.

All equipment installed in the workshop is networked via this software, enabling unified real-time monitoring and display on a single computer terminal.

Images are labeled according to the locations of the preheating and vertical furnaces covered by each thermal camera, facilitating quick location and monitoring by staff.

Temperature alarm zones can be set along the cable’s path, and alarms are triggered automatically if temperatures exceed preset thresholds.

6.How to Capture a Thermal Image of Premium Quality?

Please refer to the following suggestions for using a thermal camera to capture a thermal image of premium quality:

- Select thermal cameras with high thermal sensitivity for scenarios with small regional temperature differences.

- Choose appropriate products and temperature measurement modes depending on the scenario and temperature range.

- Use automatic measurement first, then enable the temperature scale function. Manually set the temperature scale minimum and include the previously measured temperature range to enrich image details.