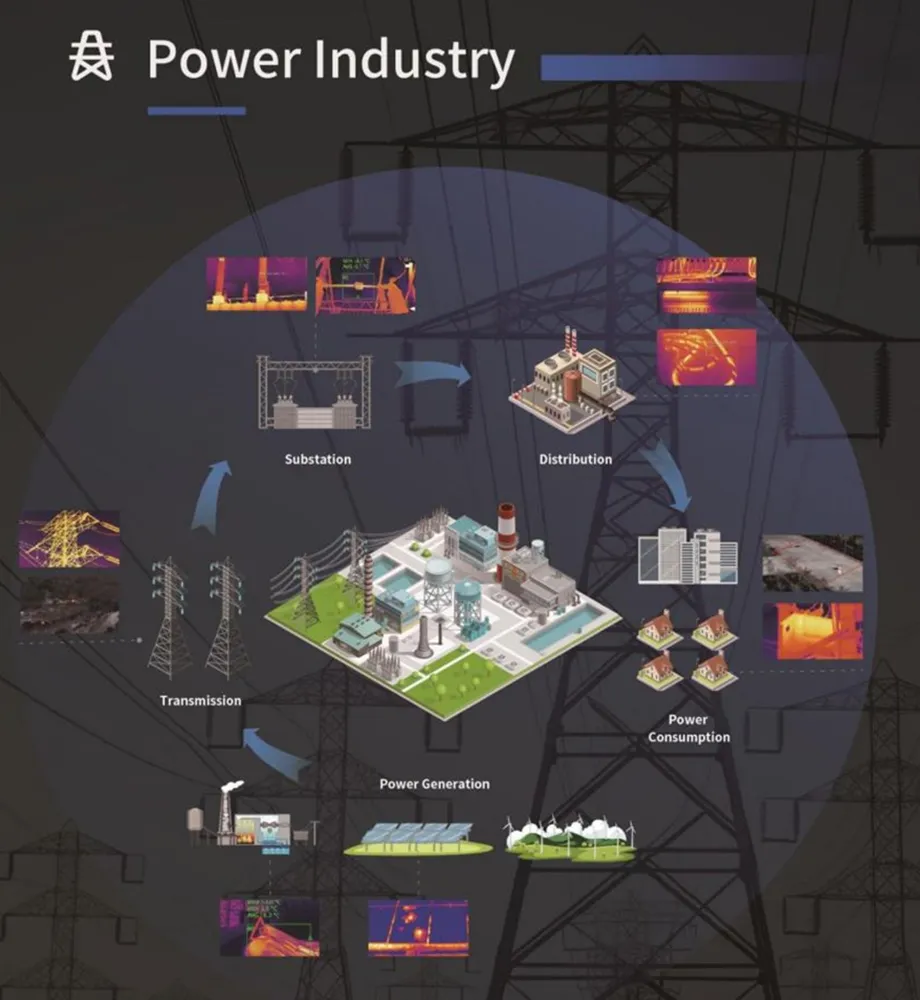

The power system consists of power generation, transmission, transformation, distribution, and consumption. Substations serve as the core hub in the system, responsible for regional voltage transformation and power supply. Hence, it is crucial to ensure their safe operation. As the power system evolves towards high capacity and high voltage, the stable operation of devices becomes key in O&M management.

Electric devices fail in various forms, most of which are accompanied by overheating. Therefore, real-time temperature monitoring is an effective means to ensure the reliability of the power supply. Infrared thermal imaging technology is an advanced detection method that enables non-contact online monitoring, allowing for the timely detection of abnormal overheating points.

Raythink Technology offers a variety of infrared detection products tailored for the power industry. Those products are widely applicable in scenarios such as transformers, cables, and generators, giving outstanding performance in device status assessment, defect investigation, and preventive maintenance, contributing to the safe and stable operation of the grid.

Thermal Imaging Application for the Electrical Grid

1. Transformer Main Body Fault Detection

The transformer is one of the most critical components in the power system. It is primarily responsible for power transmission and voltage transformation. It consists of the main body, cooling system, voltage regulation device, protection devices (such as the gas relay, oil conservator, and temperature measurement device), lead-out bushings, etc.

Currently, infrared temperature measurement is widely used for assessing the operating status of transformers as a non-contact live detection method. Infrared thermal imaging technology can be used to effectively identify various abnormal temperature rises and anomalies in the transformer main body, oil conservator, bushings, coolers, and control circuits.

A transformer’s main body consists of a core, windings, an oil tank, insulating oil, etc. Limited by its large structure and complex internal oil circulation system, it is hard to recognize internal defects within the transformer. That said, infrared thermal imaging can still effectively recognize external anomalies such as localized overheating caused by magnetic leakage flux. Common overheating defects can be visually presented through thermal images, which can be used to assist in fault analysis and warning.

2. Transformer Bushing Fault Detection

Transformer bushings are insulation components used to connect the high- and low-voltage leads within a transformer to the outside of the oil tank. They not only provide insulation between the leads and the ground but also serve to secure the conductors while allowing for continuous load current.

Depending on their structure, bushings can be categorized into capacitive, oil-filled, and porcelain ones, respectively. Among them, capacitive bushings consist of a conductive rod, capacitive screen, insulating oil, and external porcelain sleeve and are primarily used in transformers operating at a voltage of 35kV and above, where the likelihood of failure is relatively high.

Infrared detection technology can be used to effectively recognize various defects, such as low oil levels in the bushing and abnormal dielectric loss in the main insulation. Common overheating defects can be vividly presented through thermal images, as shown in the figure below.

3. Current Transformer Fault Detection

Current transformers are critical components that connect the primary system with the secondary system. They mainly convert high voltage and high current into low voltage and low current for measurement and protection by secondary devices. The power system accommodates many current transformers, whose performance directly impacts the reliability of the power supply system.

Based on the type of insulating medium, current transformers can be categorized into oil-filled capacitive ones, SF₆ gas-insulated ones, and solid insulating ones suitable for a voltage of 35kV and below. Among them, oil-filled capacitive current transformers are the most widely used. They primarily consist of the primary conductive circuit, capacitive screen, insulating oil, secondary coil, and external porcelain shell.

Infrared detection technology can be used to effectively identify thermal defects caused by current, such as overheating at primary terminals, as well as thermal defects caused by voltage issues, such as excessive dielectric loss. The temperature change trends of the device can be vividly presented by combining the technology with historical temperature curve analysis, providing intuitive and reliable data support for the evaluation of the device’s operating status.

4. Voltage Transformer Fault Detection

Voltage transformers are key components that connect the primary system of the grid with the secondary system. They proportionally convert high-voltage signals into standard low-voltage ones for measurement, protection, and control by secondary devices.

Based on their structure, voltage transformers can be divided into electromagnetic ones and capacitive ones. Among them, capacitive voltage transformers, thanks to their excellent performance, are widely used in power systems at 110kV and above that use the neutral point to directly ground. This type of transformer consists of a voltage-dividing capacitor unit and an electromagnetic unit, fulfilling both measurement and protection functions.

Because capacitive voltage transformers operate in high-voltage environments, they may experience abnormal internal heating due to voltage issues. Infrared detection technology can be used to effectively recognize various thermal defects in capacitive voltage transformers caused by voltage issues, providing important evidence for the safe operation and fault warning of the device.

5. SF₆ Gas Leakage Detection

Sulfur hexafluoride (SF₆) gas is currently the most commonly used insulation and arc-extinguishing medium in high-voltage electric devices and is widely applied in key devices such as transformers, bushings, circuit breakers, current transformers, and switchgear. Those devices hold significant importance in substations. Any leakage or fault can easily disrupt the stable operation of the grid and even lead to device damage.

Traditional methods of SF₆ gas leakage detection, such as sniffers or soap bubble tests, can identify the presence of gas leakage but struggle to accurately locate the leakage points. Worse still, they are cumbersome, less efficient, and have limited reliability under complex conditions.

In contrast, the handheld thermal gas leakage camera allows for visual observation of SF₆ gas leakage based on uncooled infrared detection technology featuring high sensitivity and high spatial resolution. This technology supports non-disruptive, remote, and real-time leakage point localization and leakage intensity assessment, generating intuitive infrared images. It effectively enhances detection efficiency and accuracy, significantly simplifies the operational process, and minimizes safety and economic risks related to gas leakage.

6. Circuit Breaker Fault Detection

Circuit breakers are one of the most critical switchgear in the power system. They are primarily used to interrupt and close circuits under normal operating conditions, as well as to cut off short-circuit currents during fault conditions. Their performance directly affects the safety and reliability of grid operations.

Based on the arc-extinguishing medium used, circuit breakers can be classified into sulfur hexafluoride (SF₆), oil, and vacuum. Among them, SF₆ circuit breakers are widely applied due to their excellent insulation and arc-extinguishing properties. An SF₆ circuit breaker is typically composed of the main body, voltage equalizing capacitor, operating mechanism, and control circuit. Infrared detection technology is mainly used in the routine inspection of high-voltage circuit breakers to identify overheating defects caused by current.

Take the porcelain column circuit breaker. Its main body consists of an arc-extinguishing chamber, a support porcelain bottle, and a transmission mechanism. Infrared thermal imaging can be used to effectively detect the following common overheating defects:

- Overheating at external terminals: The thermal image shows localized high-temperature areas centered around the power strip, which are mainly caused by poor contact due to loose terminal bolts or oxidized contact surfaces.

- Abnormal temperature at the end of the arc-extinguishing chamber: The thermal image often reveals overheating areas around the top cap or bottom flange, which are typically caused by poor contact at the moving and stationary contacts and intermediate contacts.

- Localized abnormal temperature on the surface of the porcelain sleeve: This manifests as a slight temperature rise in specific areas of the porcelain sleeve, with minimal temperature difference compared to similar devices, the possible causes being dirt accumulation or fine cracks.

- Abnormal temperature in current transformers: This is commonly caused by poor contact in the secondary circuit or open circuits. Infrared detection can promptly capture those temperature anomalies, assisting in fault diagnosis.

7. GIS Device Fault Detection

GIS (Gas Insulated Switchgear) is a technology that packages high-voltage electrical components, excluding transformers, into a metal enclosure according to the main connection method, using sulfur hexafluoride (SF6) gas as the insulating medium. The device is compact, reliable, and low-maintenance, making it widely used in medium- to high-voltage substations.

Infrared thermal imaging detection technology can be used to effectively recognize abnormal temperature rises in GIS during operation. Common defects include overheating at conductive circuit terminals and overheating of metal accessories, which are typical current-induced thermal issues. The GIS tank usually consists of metal conductive circuits, bowl-shaped insulators, SF6 gas, and a metal shell. When anomalies occur at these components, the heat sources can be accurately located using infrared images.

Other common thermal defects include overheating generated due to surface contamination of GIS lead-out bushings and poor contact at terminal connections, and eddy current losses in wall bushings due to the structure or shielding. Those comprehensive thermal defects can be initially assessed through three-phase transverse temperature comparisons to assist in field diagnosis. Infrared detection plays a crucial role in the status assessment and hazard identification of GIS.

8. Isolating Switch Fault Detection

Isolating switches are one of the most widely used types of high-voltage switching devices. They safely isolate related electrical devices from the live grid during device maintenance or system operation mode conversion. An isolating switch typically consists of a conductive circuit, post insulators, and an operating mechanism. Due to the frequent operation and multiple conductive terminals associated with isolating switches, the probability of overheating is relatively high, making infrared detection particularly important for monitoring their operating status.

The conductive circuit is generally fixed to the base by post insulators. Its key components include the moving contact and conductive rod driven by the operating porcelain bottle, a fixed stationary contact, and terminals connecting busbars or other devices. Due to its structural complexity with multiple terminals, the conductive circuit often suffers from the following defects:

- The temperature exceeds 130°C at the soft terminal of the stationary contact of 220kV isolating switches, often caused by poor contact

- The temperature difference exceeds 15K between power strip phases for 110kV isolating knives, typically due to looseness or oxidation of the terminal bolts.

- The isolating knives may suffer unstable resistance among their multiple conductive terminals, which can also lead to current-induced overheating.

Regarding the post insulator, infrared detection can effectively recognize localized temperature rises caused by surface contamination and insulation defects such as cracks, because of structural stress or aging. As a means of live detection, infrared thermal imaging technology plays a crucial role in fault warning and precise O&M of isolating switches.

9. Lightning Arrester Fault Detection

Lightning arresters are mainly used in power systems to limit overvoltage caused by operations and lightning strikes, thereby protecting electrical devices from overvoltage surges. Currently, metal oxide arresters are widely used across various voltage levels in the grid due to their fast response, low residual voltage, and high current-carrying capacity.

In practical operation, lightning arresters often experience failures due to internal moisture ingress, especially in cases of poor manufacturing processes or inadequate sealing, where rainwater or humidity can easily infiltrate into the arresters. This leads to a decrease in insulation performance, potentially resulting in partial discharge or even breakdown. Infrared thermal imaging technology, which features non-contact and real-time detection, can recognize temperature anomalies at the early stages of moisture ingress, allowing for timely hazard detection.

Moisture ingress in a lightning arrester increases internal leakage current, resulting in significant overheating detectable as localized temperature rises with voltage-induced heating characteristics on thermal images. In such cases, infrared detection plays a critical role in evaluating the operating status and providing fault warnings, enabling O&M personnel to promptly identify potential defects.

10. Defect Diagnosis for Transmission Equipment

Transmission lines are primarily composed of foundations, towers, conductors, lightning wires, insulators, fittings, and grounding devices. Deterioration of line insulators, such as surface contamination or cracking, can severely lead to a decline in insulation. The presence of zero-value and low-value insulators increases the risk of accidents of transmission line tripping due to insulator breakdowns. If crimping tubes have poor contact with the conductors, the conductors may overheat and be pulled out of the tubes, easily resulting in wire breakage accidents.

Poor construction or maintenance quality can lead to the slipping of improperly secured crimping fittings or the breaking of strands at the terminals, loose bolts, and overheating of parallel groove clamps used by direct current lines, threatening the operational safety of the lines or resulting in forced outages.

Thermal cameras can identify thermal risks posed by deteriorated insulators, grounding wires, clamps, or other connection fittings. Specifically, the dual-spectrum PTZ PC2 can be deployed for a 360° autonomous cruise. The device can also be used jointly with the handheld routine inspection device to monitor key parts such as clamps, joints, and insulators in real time. Key monitoring of components, such as online insulator detection, clamp detection, and cable terminal detection, is configured online through tools such as points, lines, and boxes to warn high temperature in real time and locate faults accurately. In that way, transmission lines will operate securely.

11. Temperature Monitoring of Power Cable

Power cables are critical components in the power system used for electricity transmission. They typically consist of conductors (or conductive cores), insulation layers, shielding layers, filling layers, inner protective layers, and armor layers. Infrared thermal imaging detection technology can be used to effectively recognize various defects during cable operation, including current-induced thermal defects such as overheating at terminals, as well as voltage-induced thermal defects like moisture ingress and insulation deterioration of power cables.

In recent years, dual-spectrum fusion thermal cameras, commonly known as dual-spectrum cube cameras, have been widely used for monitoring during cable operation. Such devices are compact, making them easy to install in confined spaces like cable trenches and ducts. They can be deployed at multiple points to monitor in real time temperature changes of the power cable and are capable of providing multi-level high-temperature alarms. By analyzing temperature trends and providing real-time warnings, they help detect potential faults in advance, thus significantly reducing the probability of accidents and enhancing the O&M efficiency and safety of the power supply system.

12. Forest Fire Monitoring for Transmission Lines

Forest fires in transmission line areas are unpredictable and random, resulting in significant losses in a short period. Hence, it has become a top priority to rapidly detect and extinguish forest fires in those areas. We believe that it is impossible to completely prevent forest fires in transmission line areas. In that case, the ideal solution to protect transmission lines and forest resources is to shorten the fire detection time and prevent the spread and escalation of fires.

Infrared dual-spectrum forest fire monitoring is the most direct and effective method. Initially, personnel inspection was used, evolving into camera monitoring, all aimed at directly monitoring situations through visual means. However, due to factors such as human eye fatigue and the overwhelming number of visual inputs, video monitoring often fails to achieve its intended effects, becoming more of a post-event query record. While it can help address some issues, our primary goal is to prevent abnormal events from occurring, nipping them in the bud. To achieve this, we must address the limitations of visual monitoring. We will provide infrared dual-spectrum forest fire monitoring and alarm technology, utilizing machine vision and machine intelligence for prevention, ensuring effective 24/7 monitoring.

13. Perimeter Protection for Substations

The infrared thermal imaging technology can be applied in the perimeter security monitoring of substations to greatly enhance safety protection ability and monitoring efficiency. Thermal cameras can clearly detect and identify perimeter intrusion targets day and night in any weather conditions, enabling real-time monitoring around the clock.

Thermal imaging technology empowers perimeter protection for substations with unprecedented reliability and intelligence. It performs all-weather and high-precision monitoring and combines with intelligent recognition and early warning mechanisms to make the security management of substations more efficient, precise, and proactive. This not only cuts labor costs and lowers safety risks but also significantly enhances the operational safety and stability of power facilities.

14. Monitoring for Electrical Cabinets in Power Distribution Rooms

In data center rooms, infrared monitoring devices can be deployed within critical electrical cabinets to achieve round-the-clock monitoring of critical components such as electrical contacts, switches, and junctions. When abnormal overheating occurs at the contacts due to overload operation or poor contact, the system can promptly capture the temperature anomaly and instantly push alarm information to the background O&M personnel. This enables quick responses and fault handling, thereby comprehensively enhancing the safety and operational reliability of the electrical system.

Advantages of Thermal Camera for Electrical Grid

- Non-contact and safer: Infrared thermal imaging technology is a passive, non-contact detection and identification technology. It features long-distance, non-contact, non-sampling, non-disintegration, accurate, and rapid diagnostics of device status. This technology can monitor and diagnose the electrical device faults in real-time online without affecting their operation.

- Intuitive imaging and accurate fault location: Infrared thermal imaging technology is unaffected by electromagnetic interference and can accurately track thermal targets from a long distance. The temperature field is visible, automatically capturing high-temperature hidden danger points and presenting fault points on devices. This allows for qualitative and quantitative assessments of the nature, location, and severity of defects.

- Operating status trend analysis, hidden danger prediction, and warning: Device temperature is collected regularly and intuitively presented in a temperature change trend chart. By analyzing operating patterns of the device and identifying abnormal high-temperature risk points, it provides data support for daily maintenance, fault warnings, and defect analysis, thus enabling early detection, early warning, and early repairs.