As an important material with a wide range of applications, glass is widely used in many fields, such as construction, automobiles, and electronics. In the glass manufacturing process, quality control and process optimization are crucial. Especially in the high-temperature thermal process involved in glass production, any slight abnormality may affect the quality of the final product.

Challenges in the Glass Manufacturing Process

In the glass manufacturing process, the melting furnace, tin bath, and annealing furnace are regarded as the three core thermal devices. Their long-term operational stability and thermal energy efficiency directly determine the production efficiency and product quality. However, in actual operation, these devices face many challenges that are difficult to monitor accurately:

1. Melting Furnace

Its refractory materials will gradually burn out in a high-temperature environment, causing a “heat leak” phenomenon. This type of heat loss is often difficult to identify with the naked eye, and the trend of change is not easy to control. At the same time, the thickness of the pool wall decreases after being eroded by molten glass. Traditional methods rely more on empirical judgment and lack objective and real-time data support.

2. Tin bath and annealing furnace

The sealing and thermal insulation performance of the device directly affects the quality of glass forming and cooling. However, by using the current conventional technical methods, it is difficult to monitor the thermal state of specific parts of the tin bath and annealing furnace in a refined and continuous manner.

Infrared Thermal Imaging Solutions to Address These Challenges

Infrared thermal imaging technology, as a non-contact and high-accuracy temperature field analysis tool, provides a breakthrough solution to the above problems. Its core advantage is that it can quickly scan and image a large area, obtain the real-time change trend of temperature distribution, and thus realize abnormal thermal state detection of key parts of the device.

In recent years, infrared thermal imaging technology has been gradually promoted and applied in the glass industry, playing an important role in key links such as glass melting, forming, and quality control. It not only improves production transparency and decision-making efficiency, but also significantly improves product yield and energy utilization efficiency. Therefore, it has become an important boost for glass manufacturing enterprises to achieve intelligent upgrading.

Application of Thermography in the Glass Industry

1. Monitoring of Furnace Health

In the glass manufacturing process, the melting furnace is a core device, so its operating status is directly related to production safety and product quality. However, due to the high-temperature environment, traditional contact temperature measurement devices are limited in application inside the furnace, with a short service life and frequent maintenance. In contrast, infrared thermal imaging technology has become an important means of monitoring the operating status of melting furnaces with its non-contact and high-resolution characteristics.

Furnace Lining Status Assessment

The thermal camera can monitor the temperature of furnace linings around the clock and accurately identify local overheating or damaged areas of refractory materials. For example, when the local temperature gradient exceeds 50°C, it can be preliminarily determined as a potential structural abnormality. The early warning mechanism can effectively prevent safety accidents such as molten glass leakage, reduce maintenance costs, and extend the service life of the device.

Electrode and Burner Optimization Control

By obtaining the real-time temperature field distribution of electrodes, it can assist in optimizing power supply parameters and burner layout, thus regulating the temperature uniformity in the furnace, preventing local overheating or cold spots, reducing product quality defect rates (such as bubbles and streaks), and improving the stability and energy efficiency of the melting process.

Joint Sealing Status Monitoring

Heat leakage from the sealing joint in the furnace structure often leads to increased energy consumption and the intrusion of external cold air, which disturbs the internal atmosphere. Infrared thermal imaging can quickly detect heat leakage parts, assist in evaluating the aging degree of ceramic fiber seals, and guide regular replacement to ensure the airtightness and thermal efficiency of the furnace body.

2. Monitoring of the Tin Bath and Annealing Furnace

The tin bath is the core forming device of the float glass production line. The molten glass flows from the flow channel onto the molten tin in the tin bath, and then naturally flattens and expands. After being controlled by the mechanical pulling, flange, and edge-pulling machines, it forms a glass ribbon with the required width and thickness and gradually cools down during travel before leaving the tin bath. The temperature measurement and control of the glass plate in the entire tin bath are very important for producing high-quality glass.

The thermal camera can detect the real-time temperature and lateral temperature difference of the formed glass plate at the outlet of the tin bath, so that once any abnormal temperature difference occurs, it can be handled in time to ensure the qualified rate of glass forming. Besides, by scanning and photographing the movable edge seal and breast wall of the tin bath, the sealing condition of the tin bath can be grasped clearly. By scanning and photographing each area at the bottom of the tin bath, abnormal conditions at the bottom of the bath can be checked to provide a scientific basis for solving glass quality defects.

The temperature of glass after forming is very high, and an annealing process is required to reduce the thermal stress of glass products. The infrared scanning temperature measurement thermal camera can continuously scan and measure the temperature of the glass ribbon in the entire plate width direction in the annealing furnace. It helps monitor the surface temperature of the glass plates in each area of the annealing furnace and control the lateral temperature difference, as well as understand the cooling trend of the glass. In addition, by scanning and photographing around the annealing furnace shell and rollers, the insulation status of the annealing furnace can be grasped.

3. Temperature Uniformity Control of Molten Glass

The temperature uniformity of molten glass directly affects the quality of glass products. Infrared thermal imaging technology can help operators intuitively see the temperature difference between different areas of molten glass so that they can adjust the burner layout and fuel flow in time to make the molten glass reach the ideal uniform temperature and reduce product defects caused by uneven temperature. The temperature uniformity of molten glass directly affects the quality of glass products.

Using infrared thermal imaging technology, operators can intuitively see the temperature differences in different areas of the molten glass and timely adjust such process parameters as burner layout and fuel flow to make the molten glass reach an ideal uniform temperature and reduce product defects caused by uneven temperature, such as stress concentration and fringes.

Infrared thermal imaging technology can be used to perform non-contact scanning of the surface and deep temperature of the molten glass and generate a visual heat distribution map to quickly discover areas with uneven temperatures (temperature difference accuracy up to ±1°C) and guide process adjustments to improve the homogenization level of molten glass.

Temperature Management of the Tin Bath and Annealing Furnace

It is to monitor the real-time temperature distribution of the tin bath in the float glass production to ensure the stability of glass ribbon forming. The analysis of the temperature gradient in the annealing furnace can optimize the cooling rate, reduce the internal stress of the glass, and prevent the risk of self-explosion.

4. Temperature Monitoring of Mold

During the glass pressing or blowing stage, the temperature of the mold plays a key role. Infrared thermal imaging can quickly measure the surface temperature of the mold and help operators determine the heat dissipation of the mold. This can prevent glass adhesion caused by local overheating or cracks caused by cooling too fast and improve forming accuracy (such as controlling the mold temperature difference within ±5°C). Through temperature feedback, the mold cooling system can be accurately adjusted to ensure that the mold temperature is within the optimal process range, thus improving the qualified rate of formed products.

5. Monitoring of Glass Tempering Process

Tempered glass is widely used in fields such as building curtain walls and car windshields for its high strength and high safety.

During the tempering process, glass needs to be heated quickly and evenly to near its softening point and then cooled rapidly. Infrared thermal imaging technology can be used to monitor the entire heating process of glass in the heating furnace to ensure that each part of each piece of glass can reach the preset tempering temperature, thus preventing uneven tempering stress caused by local temperature differences and reducing the risk of spontaneous explosion.

In the cooling process, it can be used to monitor the temperature changes on the glass surface and optimize the wind speed and direction of the air cooling system to achieve a uniform cooling effect on the glass and improve the tempering quality.

6. Monitoring of Glass Coating Process

The coating quality of functional coated glass (such as heat-insulating and UV-resistant coated glass) is closely related to the substrate temperature during the coating process. Infrared thermal imaging can be used to measure the temperature of the glass substrate in the coating chamber in real time to ensure that the coating material can be evenly deposited under suitable temperature conditions. If the temperature is too high or too low, it may cause problems such as poor coating adhesion and uneven coating thickness, affecting the optical performance and service life of coated glass.

Precise temperature control helps to improve the coating yield and produce coated glass products with stable performance and high quality.

7. Temperature Monitoring of Automotive Glass Heating Wire

Temperature monitoring is also required during the production of some special-purpose glass, such as automotive glass. Keeping automotive glass clear is a basic condition for safe driving, and it has high requirements for temperature changes. Therefore, temperature measurement and analysis are very important.

The traditional measurement method uses thermocouples and data collectors for temperature analysis. In addition to low detection efficiency, the thermocouples are temperature-conductive, which may affect the temperature field of the glass itself when the glass heats up, causing interference with the measurement.

The thermal camera can be used to intuitively obtain the temperature field distribution during the reheating process of the automobile windshield resistance wire to help improve and optimize the heating speed and temperature rise requirements of the automobile rear windshield resistance heating wire, and check for faults such as windshield resistance heating wire breakage and uneven temperature rise.

Temperature analysis of the rear windshield is mainly used to detect the uniform distribution of resistance wires throughout the glass and the heating speed of the resistance wires. Therefore, the thermal camera can quickly and conveniently obtain the thermal image of the rear windshield during the heating process of the resistance wire to help analyze the temperature distribution of the resistance wire and the temperature rise trend of the entire glass. This can prevent local heating of the glass and damage to the glass due to uneven distribution of resistance wires or abnormal resistance at a certain point. If the resistance wire is heated too quickly, causing the temperature inside the glass to rise too fast, while the temperature change on the surface of the glass is small, the glass may burst due to thermal expansion and contraction.

8. Safety Routine Inspection

The handheld thermal imaging cameras complement each other with fixed online devices. For non-fixed devices that cannot be inspected overall or devices in key areas or of hidden high-temperature dangers, periodic manual inspections can be performed to monitor temperature, determine the cause of abnormalities, and carry out preventive maintenance in time.

The handheld routine inspection thermal camera can be used to conduct close-range periodic inspections, hidden danger investigations, and defect identification against high-risk points such as furnace expansion joints, module joints, maintenance door periphery, cooling water pipeline interface, burner installation position, traditional furnace firewood feeding holes, and flue gaps, and it also can upload the inspection results to the central platform in real time to form an inspection ledger.

9. Monitoring of Electrical Cabinets in Power Distribution Rooms

Manufacturing plants in the glass industry are generally equipped with multiple sets of power distribution equipment, among which the temperature monitoring of the cabinet room and distribution cabinet is particularly important because it can detect abnormal temperatures in time to avoid production being affected by power failures.

Thermal cameras are arranged in the important electrical cabinet of the equipment room in the data center to realize all-weather and uninterrupted monitoring of key points such as electrical contacts, contact switches, and line connectors. Once the contacts are abnormally heated due to overload and poor contact, the alarm information will be pushed to the background personnel on time.

Advantages of Thermal Imaging Camera

1. Preventive Maintenance and Early Detection of Leakage

It can identify abnormally low-temperature areas (cooling water leakage) or high-temperature areas (molten material seepage) to avoid explosion, fire, or spread of toxic substances.

2. Comprehensiveness and Intuitiveness

It can quickly scan a large area of glass production scenarios (such as the surface of molten glass in the furnace and the entire mold group) and intuitively display the temperature distribution image, which is convenient for process personnel to quickly understand the overall picture of the temperature field and find abnormal areas such as local overcooling and overheating.

3. Accurate Temperature Measurement

It can accurately measure the temperature of glass at different positions and, especially, accurately identify the subtle temperature differences in some key parts (such as thinner or thicker positions of glass products and mold positions with temperature differences), which helps to improve the uniformity of thickness and shape of glass products.

4. Remote Operation

It can reduce the frequency of manual inspections to avoid the risks of high-temperature burns and exposure to harmful gases.

5. Monitoring Device Temperature

It can monitor the temperature of such devices as glass melting furnaces and conveying pipelines to facilitate the timely detection of abnormal high-temperature points, predict device failures, arrange maintenance in advance, and reduce unexpected downtime.

6. High Flexibility

Parameters such as monitoring area and alarm temperature can be flexibly set according to needs to adapt to different glass production scenarios and process requirements.

7. Data Recording and Analysis

It can analyze the real-time temperature distribution status and real-time temperature information of any point within the monitoring range. At the same time, it can record temperature data and images to facilitate comparative analysis of historical data, which is conducive to summarizing production experience and optimizing production processes.

8. Environmental Adaptability

It can work in complex environments such as those with dust and smoke (such as furnace mouths) and is well applicable to temperature measurement in some harsh environments in glass production.

Raythink Thermal Imaging Application Cases

Case: Furnace Monitoring of A Glass Bottle Manufacturing Enterprise

The production of glass wine bottles is a delicate process that combines traditional craftsmanship with modern technology. Wine bottles are not only wine containers but also works of art that integrate craft aesthetics and brand culture. The gaps in the furnace, like the joints and senses of the human body, bear the core functions of releasing stress, regulating the environment, and assisting operations.

Limitations of Traditional Inspection Methods

The disadvantages of traditional detection methods are concentrated in the five major pain points, including many blind spots, slow response, low accuracy, high cost, and high risk, which makes it difficult to meet the needs of modern industry for efficient, intelligent, and safe production.

In virtue of full coverage, real-time warning, and data-drivenness, the thermal camera solution effectively makes up for the shortcomings of traditional methods, so it is an innovative direction for furnace health management.

Project Details

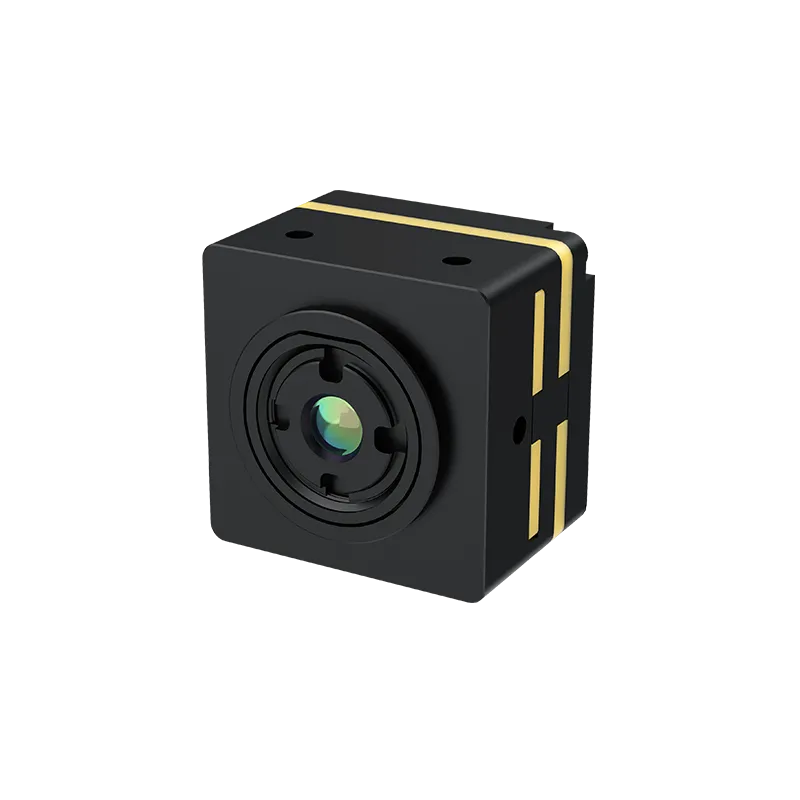

The furnace in this project is about 12 meters long, 7.6 meters wide, and 1.5 meters high. There are 85 gaps in total on three sides. The gap temperature is about 480-500 degrees. If there is a leak, the temperature will rise abnormally. The thermal imaging device uses the TN220 dual-spectrum thermal camera with a resolution of 256×192, which can provide clear image effects. Its IP grade is IP67. With its 2.0mm wide-angle lens, it can ensure to cover the major gaps of the furnace.

- Monitoring areas: Furnace expansion joints (key point of this time), module joints, and maintenance door periphery; cooling water pipeline interface, burner installation position; traditional furnace firewood holes and flue gaps.

- Implementation steps: Perform fixed installation of an online thermal camera; perform 24-hour continuous monitoring; store data at the data center.

- Determination of the cause of the abnormality combined with heat flow simulation: Local high temperature, which may be refractory layer damage or melt leakage; low-temperature zone, cooling water leakage, or insulation layer failure.

- Data analysis and decision support: Record abnormalities, increase observation frequency, trigger sound and light alarms, and arrange maintenance plans.

- Maintenance decision optimization: Develop accurate maintenance plans based on thermal imaging data (such as local repairs or overall replacement of refractory layers), and estimate the remaining life according to the gap temperature change rate to avoid excessive maintenance.

- Process improvement feedback: Analyze long-term thermal imaging data and optimize the furnace sealing design (such as adjusting expansion joint spacing); verify the thermal insulation performance of new refractory materials.