Electricity is the fundamental energy source that underpins the operation of modern society. As the national economy develops and living standards improve, the electricity demand continues to rise. However, within the vast electrical transmission and distribution systems and circuit systems, factors such as equipment aging, overloading, improper human operation, and environmental conditions can cause electrical equipment to overheat. This not only poses a serious threat to the stable operation of the power system but can also lead to incalculable losses for equipment, personnel, and the entire social economy.

Therefore, how to achieve early warning of potential hazards in electrical systems and implement effective prevention and control measures has become a key focus of widespread concern across all sectors of society.

The Importance of Thermal Imagers in Electrical Equipment Inspection

Thermal defects in electrical equipment typically refer to abnormal heating caused by internal or external factors within the equipment. These defects, based on their underlying causes, can generally be categorized as poor electrical connections, overload, insulation degradation, and other similar issues. Given the increasing risks associated with electrical safety and the limitations of traditional inspection methods, there’s a pressing need for a more efficient, safe, and reliable detection technology to enhance electrical safety management.

The advent of infrared thermal imaging technology has offered new approaches and methods for tackling this challenge. Infrared thermal imagers, as an advanced non-contact inspection tool, can rapidly capture the temperature distribution across equipment surfaces. They convert the invisible thermal radiation into clear and intuitive thermal images, enabling inspection personnel to efficiently identify thermal defects in electrical equipment, thus facilitating early warnings and fault diagnosis.

Leveraging its unique advantages, infrared thermal imagers are playing an increasingly vital role in the field of electrical equipment inspection, demonstrating irreplaceable value, particularly in the following applications.

Core Applications of Thermal Imaging for Electrical Equipment Inspection

1. Motors

Motors are among the most fundamental and crucial electromechanical drive devices in modern society, serving to convert electrical energy into mechanical energy. They are extensively used across various sectors, particularly in industrial production. If motor issues are not detected and addressed promptly, the consequences can range from a single motor becoming unusable to potentially impacting the progress of an entire production line.

Therefore, the temperature monitoring and control of motors are critically important in industrial production. However, traditional motor inspection methods have limitations such as being highly subjective, inefficient, lacking comprehensive coverage, and struggling to detect early or internal faults. This can lead to failures not being identified in time, ultimately resulting in equipment damage and production downtime.

Motors typically have specific standard operating temperatures, which are often indicated on their nameplates. Their external temperature can be indicative of their internal condition. Infrared thermal imaging technology allows for the non-contact detection of surface temperature distribution across critical components of a motor while it’s in normal operation. Experienced inspection personnel can then analyze these thermal images to identify thermal anomalies such as winding short circuits, bearing wear, rotor imbalance, and coupling damage. This enables timely preventative maintenance, helping to avoid equipment failures and production downtime.

After each inspection, the thermal images captured by the imager can be saved to track temperature trends over time. By comparing thermal images from different periods, a temperature baseline for the motor’s operation can be established. This allows for a more accurate assessment of whether current hotspots are abnormal and helps to verify the effectiveness of any maintenance performed.

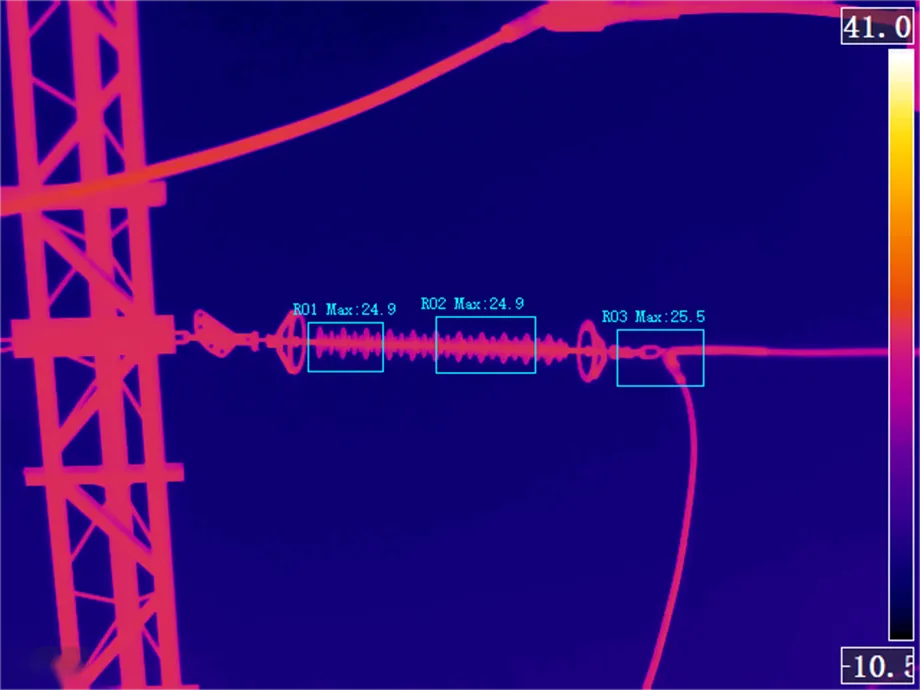

2. Voltage Insulators

Insulators generally refer to the insulating devices within power transmission systems that connect utility poles, transmission towers, and suspended cables carrying high-voltage electricity. If an insulator fails, it can lead to contact between transmission lines or between a transmission line and a tower, resulting in a short circuit that causes power outages and reduces the reliability of the power supply. This can negatively impact the public perception of the power system and lead to economic losses. Therefore, the timely detection and repair of insulator faults are critical for the safe and continuous operation of high-voltage power transmission and transformation lines.

Generally, different types of faulty insulators exhibit distinct thermal characteristics. The main types include: ① Low-value insulators: These are damaged by prolonged stress and high voltage, resulting in low resistance and high heat generation. ② Zero-value insulators: These are internally and completely damaged, having lost their insulation properties, leading to minimal heat generation and low temperatures. ③ Contaminated insulators: Surface pollution makes them conductive, causing leakage current, which results in low resistance and high heat generation.These various types of faults lead to different thermal effects on the surface of the insulators.

Traditional contact-based inspection methods are inefficient, have limited coverage, and struggle to detect early-stage defects in a timely manner. This makes them inadequate for meeting the demands of modern power grids, which require large-scale, high-efficiency monitoring.

Addressing the limitations of traditional inspection methods and leveraging the distinct thermal characteristics of different types of faulty insulators, the infrared thermal imager method has emerged as a superior alternative. Infrared thermal imagers primarily detect faults based on the thermal effects on the insulator’s surface. Under normal operating conditions with live power, the surface current on an insulator is relatively high, leading to a correspondingly higher temperature.

When an insulator has a defect, the current distribution becomes abnormal, causing temperature variations on its surface that can be quickly and visually identified by an infrared thermal imager. For instance, low-value insulators, due to their reduced resistance and increased heat generation, will appear as high-temperature areas in thermal images. Conversely, zero-value insulators, which don’t carry voltage, generate very little heat and therefore exhibit low-temperature signatures. Polluted insulators will show localized temperature increases due to increased surface leakage current.

By analyzing these unique thermal signatures associated with different fault types, potential points of failure can be effectively identified.

3. Cables

Cables are a critical component of power transmission and distribution, and their condition directly impacts the stability and safety of the electricity supply. With the rapid pace of urbanization and increasing industrial demands, cable systems are facing heavier loads, and the risk of failures is consequently rising. These failures can range from minor equipment malfunctions that affect power quality to severe incidents like fires, posing a significant threat to the safety of the power system.

Traditional cable fault detection methods, such as the Wheatstone bridge method, low-voltage pulse reflection, and surge voltage techniques, have limitations in their applicability, carry risks of electric shock and equipment damage during testing, are complex to operate, and are susceptible to external interference. To enable the rapid repair and resolution of cable faults, advanced and effective detection methods are needed for the swift localization of these issues.

Leveraging their non-contact, long-range, and real-time monitoring capabilities, infrared thermal imagers can effectively address the challenges in cable fault detection. They can monitor cable surface temperature changes around the clock. When a cable fault occurs, the temperature at the fault location typically rises. By analyzing the infrared thermal image, maintenance personnel can quickly pinpoint areas of abnormally high temperature, which indicates the location of the cable failure.

Working in conjunction with temperature measurement and analysis tools, the system can continuously monitor critical areas like cable joints with focused attention. When the temperature exceeds a predefined threshold, the system will automatically trigger an alarm and capture a thermal image in real time, immediately alerting maintenance personnel to take necessary actions. The alarm records stored by the system are valuable for fault tracing, trend analysis, and optimizing operations and maintenance, ultimately improving inspection efficiency and enhancing the safety and reliability of power delivery.

This approach not only enhances the safety and efficiency of fault detection but also reduces the consumption of manpower and resources, ultimately lowering troubleshooting costs.

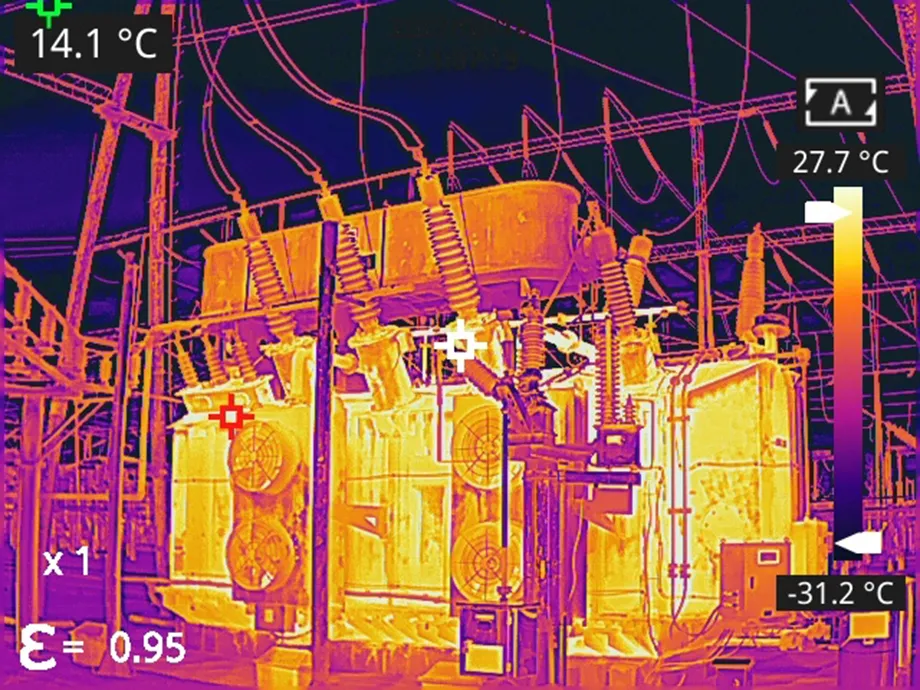

4. Transformers

Transformers alter voltage levels through the principle of electromagnetic induction. When alternating current flows through the primary winding, it generates an alternating magnetic field that is channeled through the core to the secondary winding, thereby inducing a voltage in the secondary winding. During operation, temperature fluctuations are a crucial indicator of the transformer’s health. The primary causes of abnormal transformer temperatures include:

- Poor Connections: Loose or corroded connections at terminals or bushings can increase contact resistance, leading to localized temperature anomalies. Poor internal connections can also cause localized overheating of the transformer tank.

- Overload Operation: Prolonged operation under high load conditions will cause a sustained rise in the temperature of the transformer windings, potentially resulting in overheating failures.

- Inefficient Cooling: Malfunctions in the cooling system or blockages in the radiators can impede heat dissipation, increasing the risk of overheating. Similarly, blockages in the transformer oil circulation can hinder cooling and create localized temperature differences.

- Winding or Core Faults: Short circuits within the windings, insulation degradation, or damage to the core insulation, and poor insulation in general can all lead to localized overheating.

- Stray Flux Effects: Eddy current losses caused by abnormal magnetic fields can result in the heating of the transformer tank or connecting bolts, representing energy loss.

Traditional oil temperature sensors only monitor the overall temperature, failing to pinpoint internal hotspots. They are also inefficient at detecting defects in concealed areas. Furthermore, manual inspections are limited by the safe distance required when working with high-voltage equipment, making it challenging to identify early-stage potential issues on time.

In contrast, infrared thermal imagers, with their non-contact and long-range monitoring capabilities, allow for rapid and intuitive real-time temperature monitoring of critical transformer components like the tank, bushings, and conservator, all without interrupting power. The thermal images clearly display temperature variations across the equipment surface, enabling inspection personnel to quickly pinpoint areas of abnormal heat while ensuring their safety. Furthermore, when used in conjunction with intelligent temperature analysis tools, maintenance personnel can gain in-depth insights into the equipment’s operational status, proactively identify potential issues, and achieve early warning and diagnosis of common transformer faults. This significantly improves operational efficiency and equipment safety.

5. Distribution Cabinets

Distribution cabinets are the central hubs of electrical power systems, responsible for the distribution, control, and protection of electrical energy. They house various critical components, including busbars, circuit breakers, and wiring terminals. Operating under complex long-term conditions, they are susceptible to a range of factors that can lead to safety hazards:

- Loose Connections or Poor Contact: Long-term operational vibrations, subpar installation practices, or environmental corrosion can cause connections to loosen and contact surfaces to oxidize. This increases contact resistance, leading to localized overheating and raising the risk of electrical incidents.

- Line Overload or Insulation Aging: As electricity consumption increases, wiring within the cabinet may experience prolonged overload. Additionally, insulation materials can degrade over time, reducing their dielectric strength and causing abnormal temperature increases, which compromises the operational safety of the distribution cabinet.

- Impact of Environmental Factors: Distribution cabinets situated in harsh environments with high temperatures, high humidity, and dust contamination are prone to accelerated equipment aging, increasing the likelihood of failures.

Traditional manual inspections primarily rely on experienced visual checks and contact-based temperature measurements. This approach not only necessitates power shutdowns, disrupting the normal operation of the power system, but also suffers from low inspection efficiency and limited coverage. It’s difficult to thoroughly monitor critical internal components of the distribution cabinet, leading to a risk of missed defects and increasing the potential for equipment failures and safety hazards.

In contrast, infrared thermal imagers, with their rapid response speed, high-temperature measurement accuracy, and strong reliability, have become vital tools for detecting faults in distribution cabinets. They can monitor internal temperature variations in real time, providing a continuous and precise reflection of the electrical equipment’s operational status.

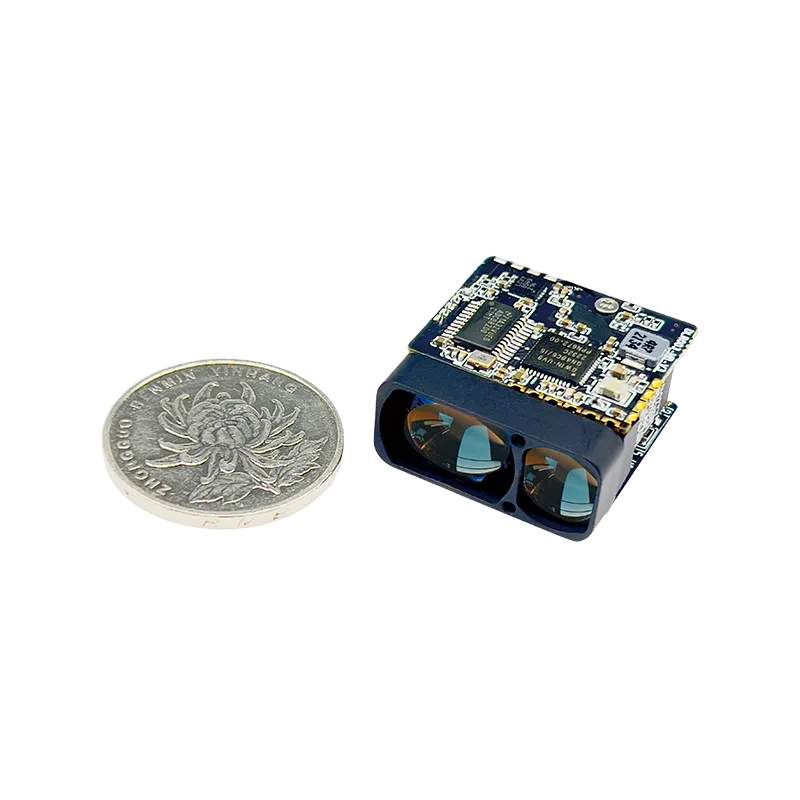

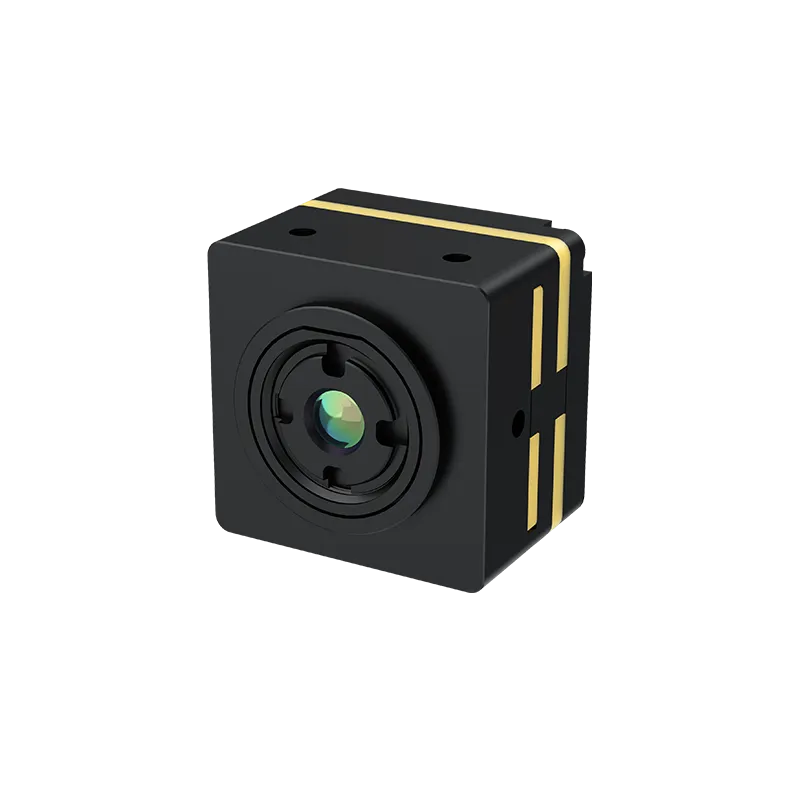

By installing compact dual-spectrum cube cameras within the cabinet, comprehensive 24/7 monitoring can be achieved, capturing abnormal temperature increases in key components (such as cable joints and fixed/moving contacts) in real time. Infrared thermal images enable maintenance personnel to quickly pinpoint abnormal areas, while the system’s real-time temperature trend analysis allows them to proactively identify temperature anomalies and develop appropriate maintenance strategies. Furthermore, if any area exceeds the set temperature threshold, the system’s multi-level zone early warning function will automatically trigger an alarm and capture a thermal image, prompting maintenance personnel to respond swiftly, thereby enhancing the safety and operational efficiency of the distribution cabinet.

Conclusion

The advantage of using infrared thermal imagers for electrical equipment inspection lies in their high sensitivity and non-destructive testing capabilities. They can quickly pinpoint problem areas in electrical equipment in a non-contact manner without requiring power shutdowns, which is crucial for reducing maintenance costs and extending the lifespan of equipment. Furthermore, they support long-range measurements and wide-area scanning, making them suitable for various applications in industries such as petrochemicals, industrial automation, and building HVAC.

If you are interested in the applications of infrared thermal imagers in electrical inspection, we encourage you to explore our products further. We offer a diverse range of infrared thermal imager models to meet the specific needs of different industries, along with professional technical support and services. Please feel free to contact our customer service team or send an inquiry to obtain more information.