Vinyl chloride is actually commonplace in our daily life. In every corner of our lives, we can find various products made of vinyl chloride, such as shopping bags, bottle caps, and other daily necessities. Vinyl chloride is an important chemical raw material, but also a hazardous chemical. Vinyl chloride is a colorless, flammable gas with an ether-like odor at room temperature, with a potential risk of leakages in chemical production, storage, and transportation. The Raythink handheld infrared gas thermal camera, one of the effective means of gas leakage detection, can visually display this invisible gas leakage, enabling quick identify the leakage position and scale.

Gas Leakage Detection of Valves and Flanges

In vinyl chloride polymerization and finished product preparation, valves and flanges are important components to ensure the pipeline system’s ingress protection rating and safety. Because of changes in process conditions, material aging, improper operation, and other reasons, these components are very likely to cause gas leakage, which will not only affect production efficiency but may also cause safety accidents.

How Does Gas Thermal Camera Help to Detect Gas Leakage?

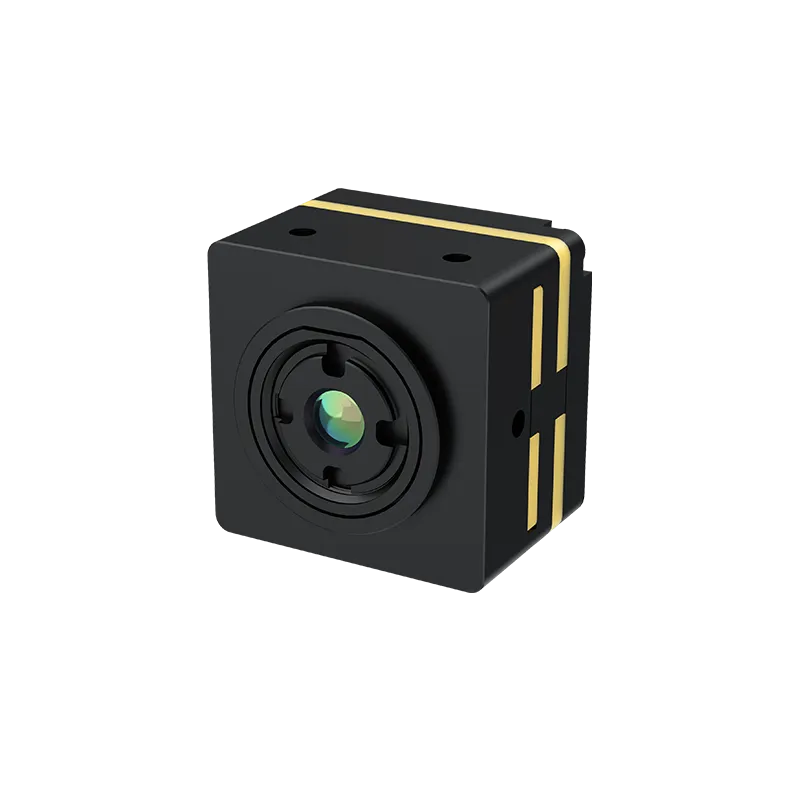

Joint routine inspections are performed using the online gas cloud thermal camera TE464G1 and the handheld infrared gas thermal camera RG600F. Online gas cloud thermal cameras are installed at detection points in key areas to achieve real-time online detection. Visual routine inspections of key components, such as transport pipelines, valves, and flanges, can be performed intuitively, efficiently, and safely, which can not only ensure the normal operation of the device but also detect abnormal situations and eliminate hidden dangers. At the same time, professionals use the handheld infrared gas thermal camera to conduct large-scale scanning and detection of the entire routine inspection area. Gas leakage can hardly be detected with our naked eyes, but it is “smoky” on the instrument display, exposing every leak position. In this way, supervisors can quickly locate the leak position and carry out maintenance and inspection.

(Use the handheld infrared gas thermal camera to conduct large-scale scanning and detection of the entire routine inspection area)

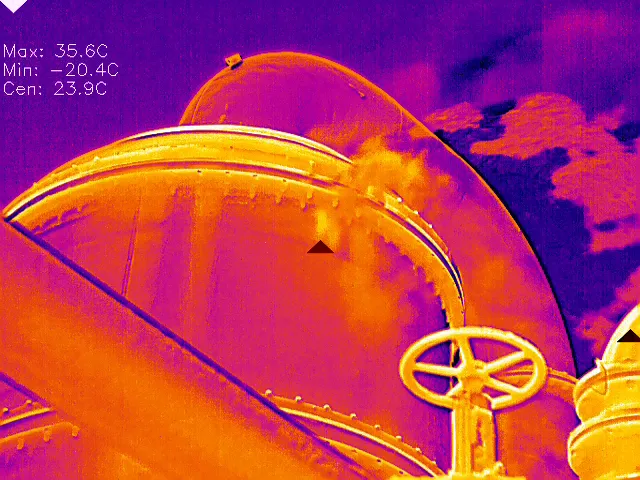

Gas Leakage Detection of Storage Tanks

Storage tanks are mainly used to store and temporarily store raw materials, intermediate products, or finished products. These storage tanks can ensure the continuity and stability of the production process and prevent material leakage or environmental pollution. When leakage occurs, we can use the handheld infrared gas thermal camera RG600F to identify the leak position and scale for further treatment.

Benefits of Using Handheld Thermal Camera

This detection method, as an important tool for gas leakage detection, has the advantages of remote measuring and non-contact detection, 24-hour monitoring, and intuitive visualization. At the same time, the Raythink Technology infrared gas detector is of high sensitivity, and able to detect tiny temperature changes, thereby discovering tiny leak positions. This is crucial to preventing potential safety accidents and ensuring the normal operation and maintenance of storage tanks.

(Use the gas thermal camera to regularly perform routine inspections of the gas leakage at the emission outlet)

Gas Leakage Detection of Emission Outlets

The process of vinyl chloride polymerization and finished product preparation involves many chemical reactions and process steps, such as cracking, polymerization, and extrusion of raw materials. Harmful gases or volatile organic compounds (VOCs) may be produced during these processes. The leakage of these substances into the atmosphere may pollute the environment and even harm human health. Therefore, through the use of a gas thermal camera, regular routine inspections of gas leakage at the emission outlets are carried out to timely grasp the gas emission situation and take appropriate measures for its management and control.

In addition, during device maintenance operations, the thermal camera can accurately determine whether the gas inside the device is exhausted, thereby effectively avoiding potential hazards imposed on maintenance personnel during the maintenance process and ensuring personnel safety.

(Use the gas thermal camera to regularly perform routine inspections of the gas leakage at the emission outlet)

We cannot ignore the risk of vinyl chloride leakage. The introduction of infrared thermal imaging gas detectors can visually display positions with hazards of gas leakage, enabling timely discovery and handling of potential leakages. In this way, the leakage risk is reduced to the minimum and the safe production of the enterprise and the health of employees are ensured. In the future, Raythink Technology will continue to insist on the innovation of infrared thermal imaging gas detection technology and contribute more products and solutions to the industry.