Photovoltaic modules are devices that absorb sunlight and directly or indirectly convert solar radiation energy into electrical energy through the photoelectric effect or the photochemical effect. As China’s new energy industry leaps forward, photovoltaic power stations have become an indispensable part of the new energy power generation sector. With the expansion of photovoltaic power station scales, the diversification of photovoltaic power station modes, and the development of distributed photovoltaic power stations, the operation and after-sales service of photovoltaic power stations become increasingly important. In particular, the emergence of household photovoltaic power stations calls for more effective photovoltaic operation and maintenance.

Why Choose Thermal Imaging for Photovoltaic Inspection?

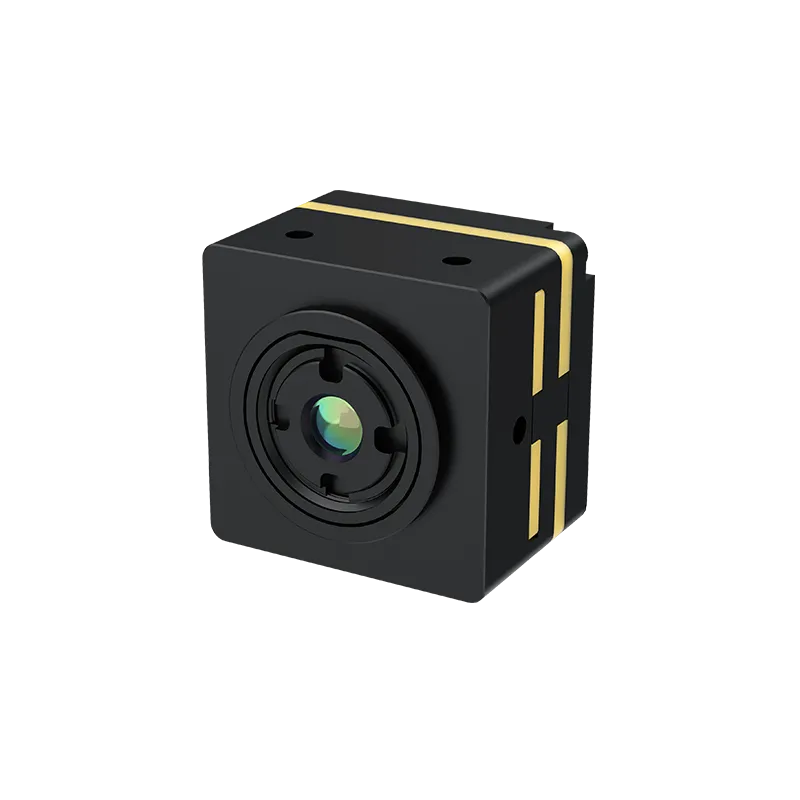

The huge installed capacity of photovoltaic power stations adds to the probability of photovoltaic power station failures, resulting in increased safety hazards. Featuring strong penetration, immunity to strong light interference, low power consumption, and long service life, the thermal camera can operate from afar under all weather conditions. It is capable of identifying concealed targets and enables photovoltaic power station operation and maintenance personnel to detect more efficiently and conveniently.

Specific Thermal Imaging Applications in the Photovoltaic Industry

1. Defect Detection of Semiconductor Silicon Wafers of Solar Panels

Solar panels, the core components of photovoltaic systems, rely on the unique properties of semiconductor materials to convert sunlight into electricity. Common semiconductor materials include silicon, germanium, and gallium arsenide. Among them, silicon is the most widely used semiconductor material.

By leveraging the feature that short-wave infrared light can penetrate semiconductor materials, short-wave infrared (0.9–1.7 μm) has become the best choice for the quality inspection of silicon wafers, silicon ingots, and finished wafers. This has greatly improved the inspection efficiency and enhanced the production process. Scanning detection of solar panels can penetrate the surface material to see the internal silicon wafer conditions. It enables rapid and accurate detection of potential problems such as hidden cracks and damages, helping to improve production line efficiency.

2. Solar Hot Spots Detection

Solar hot spots can cause severe damage to solar cell modules or systems; therefore, it is necessary to perform hot spot detection on solar cell modules, so that cells generating relatively uniform heat are combined or maintained to prevent the energy generated by the modules from being consumed by modules with hot spots. In addition, the possible impairment brought by hot spots, which may shorten the service life of solar modules or systems, can be avoided. Infrared thermal imaging converts invisible infrared radiation into visible temperature distribution images that reflect the thermal distribution on the surface of items, to clearly visualize the temperature difference of the solar panel for quick location of fault points.

3. Inverter Circuit Board Detection for Photovoltaic Panels

Electronic circuit failures generally involve short circuits, open circuits, and poor contact. Infrared rays emitted by a circuit under normal operation are different from those emitted by faulty electronic components.

In the case of a short circuit, the current is larger. The components are hotter and emitting larger infrared radiation. At this point, the thermal image is quite different from that of a normal situation. In the case of an open circuit or poor contact, the current flowing through components is almost zero, so the temperature of components is lower than that in normal operation, and there is nearly no infrared radiation. At this point, the thermal image is quite different from that of a normal situation.

By analyzing the infrared heat map, engineers get to know the temperature distribution of the entire circuit board and optimize the design and application of the circuit board accordingly.

4. Electrical Distribution Cabinet Monitoring of Solar Power Generation Systems

Prolonged exposure of electrical contacts to high temperatures can cause insulation degradation or fire. The inspection of power devices is a fundamental operation to guarantee the safety of power devices, improve the reliability of power devices, and ensure that the power devices run with a low failure rate. Thermal cameras can visualize hot spots and their temperature clearly and support coordinated image capture in the case of abnormal temperature for cause analysis and timely treatment.

5. Solar Cell or Module Inspection

During the operation of solar energy systems, defects in battery modules are the most frequently encountered. Such defects are shown as the “hot spot effect” on the infrared heat map. Defective modules cannot convert the thermal energy absorbed into electricity, so they are directly shown as “high heat”. Thermal cameras can agilely and accurately capture the minute temperature changes on the surface of the item to be measured, and enable non-contact detection of solar cells or module defects. The location of product defects is accurately visualized in the infrared heat map, making it a convenient and fast detection solution for the operation and maintenance personnel.

6. Safety Monitoring System for Energy Storage Stations

Thermal cameras can monitor the temperature distribution inside a container round-the-clock in real time and adjust the air outlet orientation of the refrigeration system or air conditioner so that the container’s temperature is intelligently controlled. They support the coordinated operation of the firefighting systems and can capture images, record videos, or set off on-site alarms and firefighting devices in case of abnormal temperatures. They also support real-time storage of visible light and infrared videos to help accident retrospect and determination of temperature rise points at a later stage.

7. Perimeter Protection for Photovoltaic Power Stations

Most photovoltaic power stations are built in unattended open areas. Thermal cameras can expose suspicious individuals approaching the energy storage station day and night. When the monitoring area is trespassed by unauthorized individuals or vehicles, the infrared thermal camera device can set off alarms in time, promoting the staff’s intervention.

Advantages of Thermal Camera for Photovoltaic Inspection

1. Intuitively Visualize Temperature Distribution

Automatically capture the hottest spot across the entire screen, visualize, and accurately locate issue points, thereby enabling routine inspection personnel to pinpoint the root cause of faults reliably and accurately, and quickly find a solution.

2. Operate from a Long Distance, No Contact, No Change of Target Structure

This feature offers several key benefits:

(1) It does not affect the surface temperature of the item to be measured, which can improve temperature measurement accuracy

(2) It does not affect the power generation efficiency, and the photovoltaic modules can be checked without disconnecting power

(3) It improves work efficiency. No operation is needed on photovoltaic modules. All you need to do is simply adjust the orientation of the thermal camera so it finds the photovoltaic panel.

3. Support Alarm and Provide Alarm Information

It supports setting high and low-temperature ranges. When the temperature reaches the setting value, an alarm will be triggered, reminding the staff to carry out further inspection or maintenance.

Application Cases of Raythink Thermal Imaging Cameras in Photovoltaic Industry

1. The Security and Fire Protection Monitoring Project of a Photovoltaic Power Plant

The security and fire monitoring project was implemented at a State Power Investment Corporation (SPIC) photovoltaic power plant to mitigate the potential fire risks caused by the power plant’s large-scale layout, complex terrain, and surrounding environment. The photovoltaic power station is located near residential areas, forests, and grasslands, where fire risks significantly increase during dry seasons in spring and autumn, as well as during sacrificial periods.

To address this challenge, the project deployed PC4 series dual-spectrum thermal imaging PTZ devices, utilizing high-point installations and a blind-spot compensation strategy to achieve comprehensive, three-dimensional monitoring of the entire power station. Each device covers a 4km radius, precisely identifying small fire sources as small as 2m×2m. By integrating intelligent temperature anomaly analysis and image recognition technology, the system quickly locates fire sources and significantly reduces the false positive rate.

Following implementation, fire response speed improved dramatically, reducing fire detection time to just a few minutes. The system’s extensive coverage ensures seamless monitoring even in complex terrains and large-scale photovoltaic power stations. Early fire detection and intervention significantly reduce device damage and production downtime risks. This project not only improves security and fire protection in photovoltaic power stations but also sets a benchmark for safety management in the new energy power station sector.

2. Infrared Thermal Imaging Facilitating the Electrical Distribution Cabinet Monitoring of Solar Power Generation Systems

During the operation of a solar power generation project, frequent failures in the power distribution system—caused by device aging and environmental factors—posed serious threats to system safety and stability. To address this issue, infrared thermal imaging technology was adopted to enable non-contact, visual, real-time monitoring of electrical distribution cabinets, providing an efficient and reliable fault diagnosis solution.

Infrared thermal imaging technology precisely addresses both external and internal faults. External faults (accounting for approximately 90%) include overheating caused by oxidation and loose connections in devices, cables, and switch contacts, with surface temperature variations that can be quickly detected. Internal faults (around 10%), such as insulation degradation and electrical circuit failures, manifest as slight temperature increases, making them difficult to be detected promptly using traditional methods.

By using thermal cameras, the project enabled real-time surface temperature scanning of electrical devices, precisely locating overheating areas caused by poor contact and oxidation. Furthermore, by combining device operating parameters with thermal imaging trend analysis, the system significantly improved the early detection of internal faults. After the implementation of the project, the fault detection rate significantly improved, achieving 100% early detection of external faults and increasing the accuracy of internal fault prediction to 85%. Additionally, routine inspection time was reduced by 50%, significantly lowering manual troubleshooting costs and effectively minimizing unplanned device downtime, ensuring the continuous and stable operation of the power generation system.

With its high efficiency, precision, and visualized monitoring capabilities, infrared thermal imaging technology not only improves the fault diagnosis capability of electrical distribution cabinets but also provides strong support for intelligent power operation and maintenance.

.webp)